1

Pulse Width Modulation

Module Descriptions & PIL Examples using the

F28069M LaunchPad Board.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

Topics:

• PWM & Duty Cycle

• ePWM Block – Modules

• Time Base

• Action Qualifier

• Deadband

• Event Time

• Solenoid Modeling, Simulation, Transfer Function Approximation, Processor in the Loop (PIL) Simulation

(requires F28069M board to be attached)

• Motor Modeling, Dynamics, Time Constant

• Using the eCap block to record PWM Carrier Period and Frequency (Example requires the F28069M board to be

attached)

2

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Basic Terminology

3

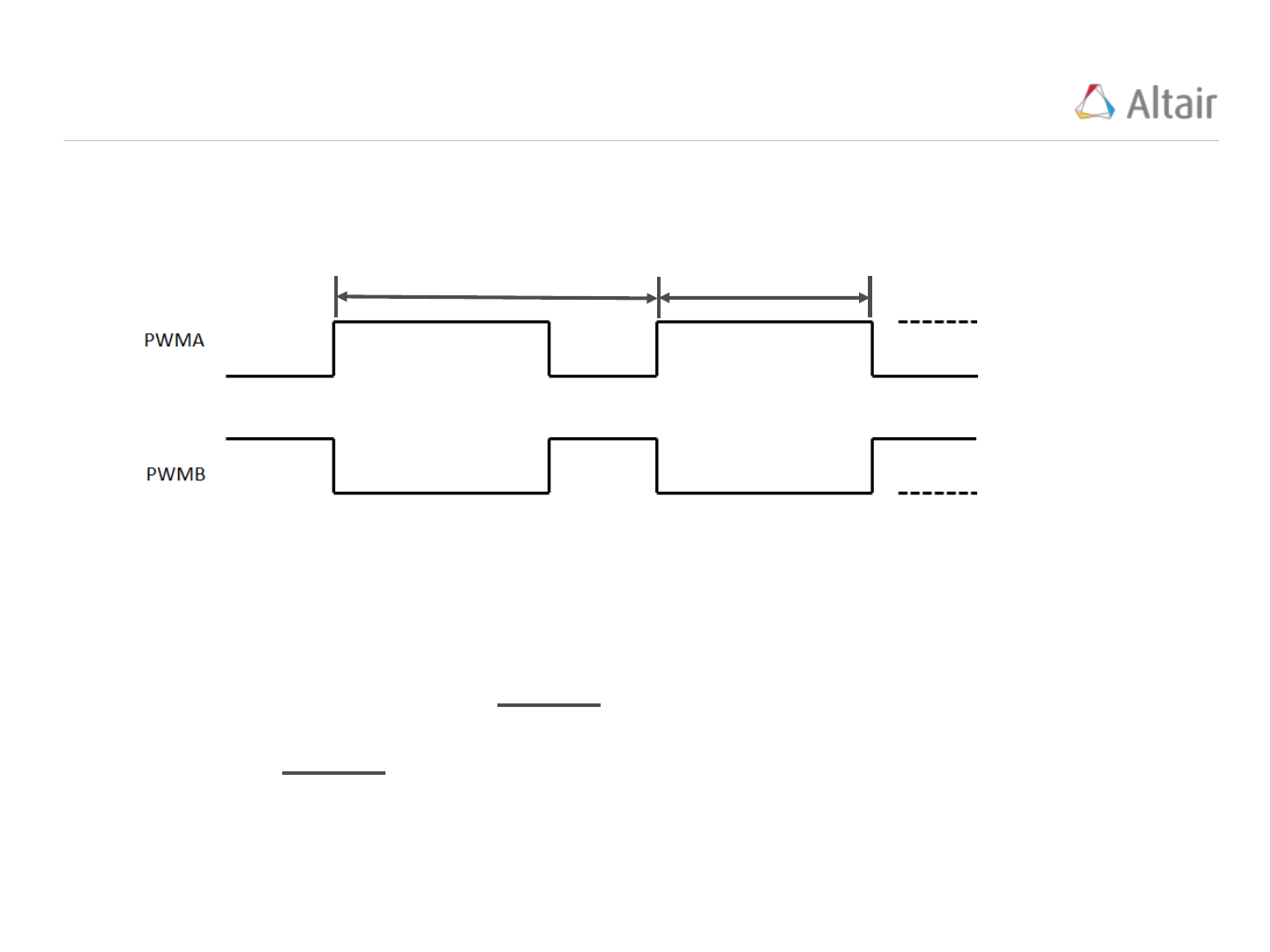

The “ePWM” block (“Embedded/F280x”) produces two PWM signals (PWMA and PWMB). These

control signals are always opposite each other; when one is high (On), the other is low (Off):

Tpwm

tOn

Tpwm = Carrier Period(sec)

Duty Cycle =

tOn

Tpwm

Fpwm = Carrier Frequency, Hz =

1

Tpwm

Three Important PWM Features:

On value

On value

Off value

Off value

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Generation

4

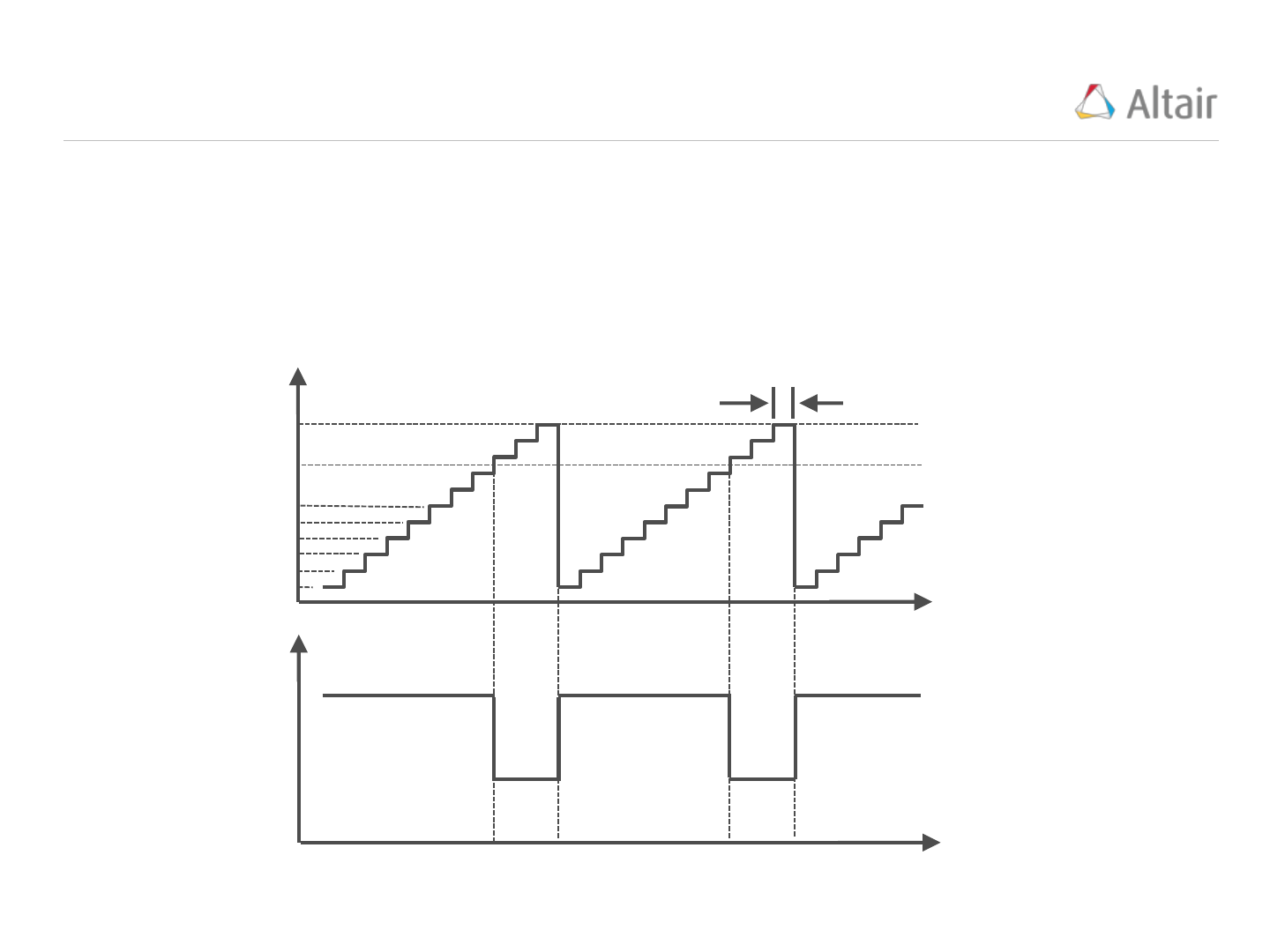

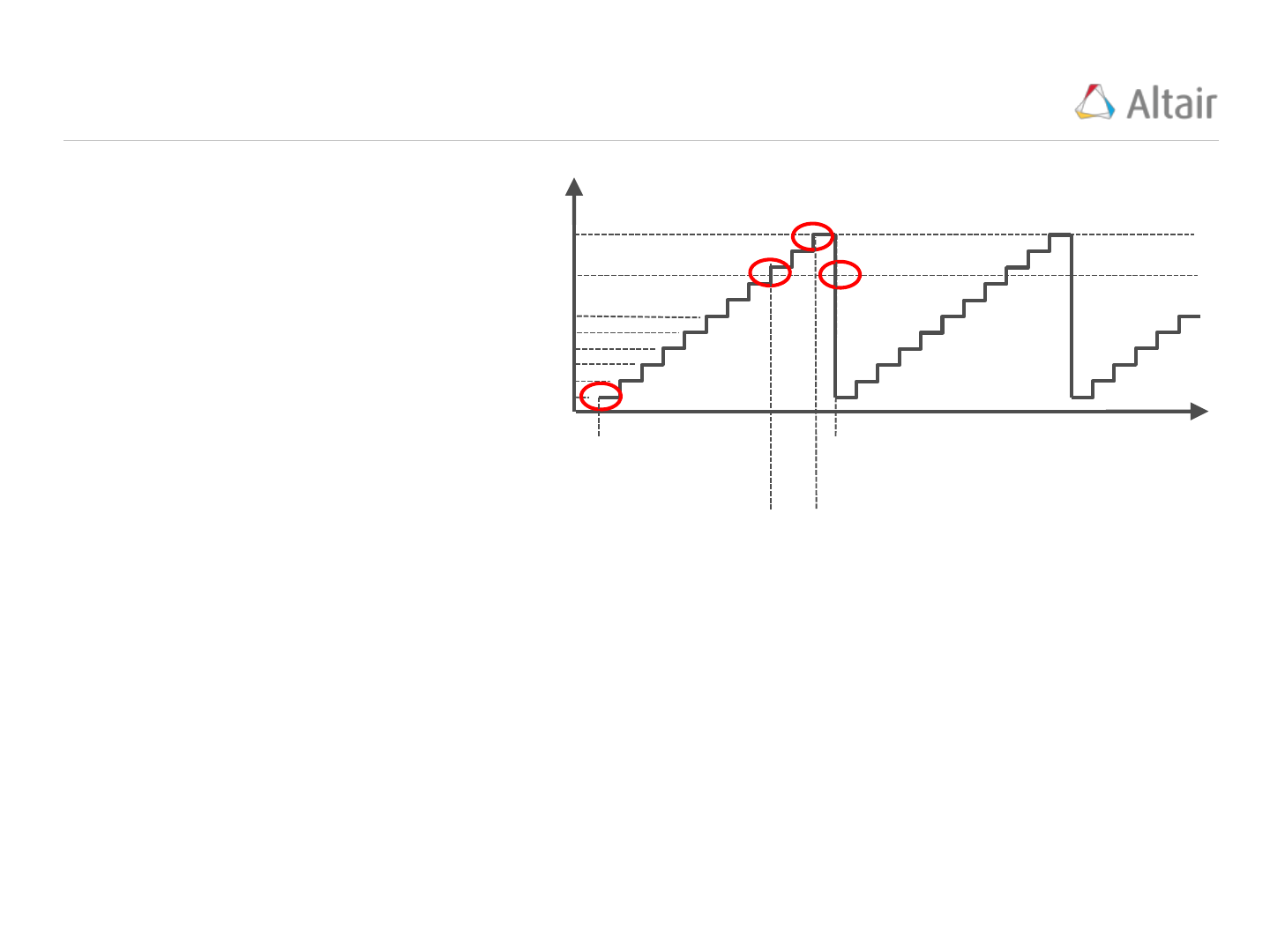

In an embedded application, the target processor produces pulses from a Time Based Clock (TBCLK).

The Time Based Clock can run at the CPU speed or a fraction of it. Pulses produced by the TBCLK

are counted as they occur forming a staircase signal whose count value at any time is monitored by a

Time Based Counter (TBCTR). When the TBCTR reaches a preset value named the Time Base

Period (TBPRD), the counter resets itself to 0 and the staircase signal repeats. PWM signals are

produced based when the TBCTR equals a Compare (CMP) value.

time

time

PWM

On value

Off value

TBCTR

(counts)

CMP value

5

4

3

2

1

0

Time Based Clock (TBCLK), (sec)

TBPRD value

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Count Mode, Period, and Frequency

5

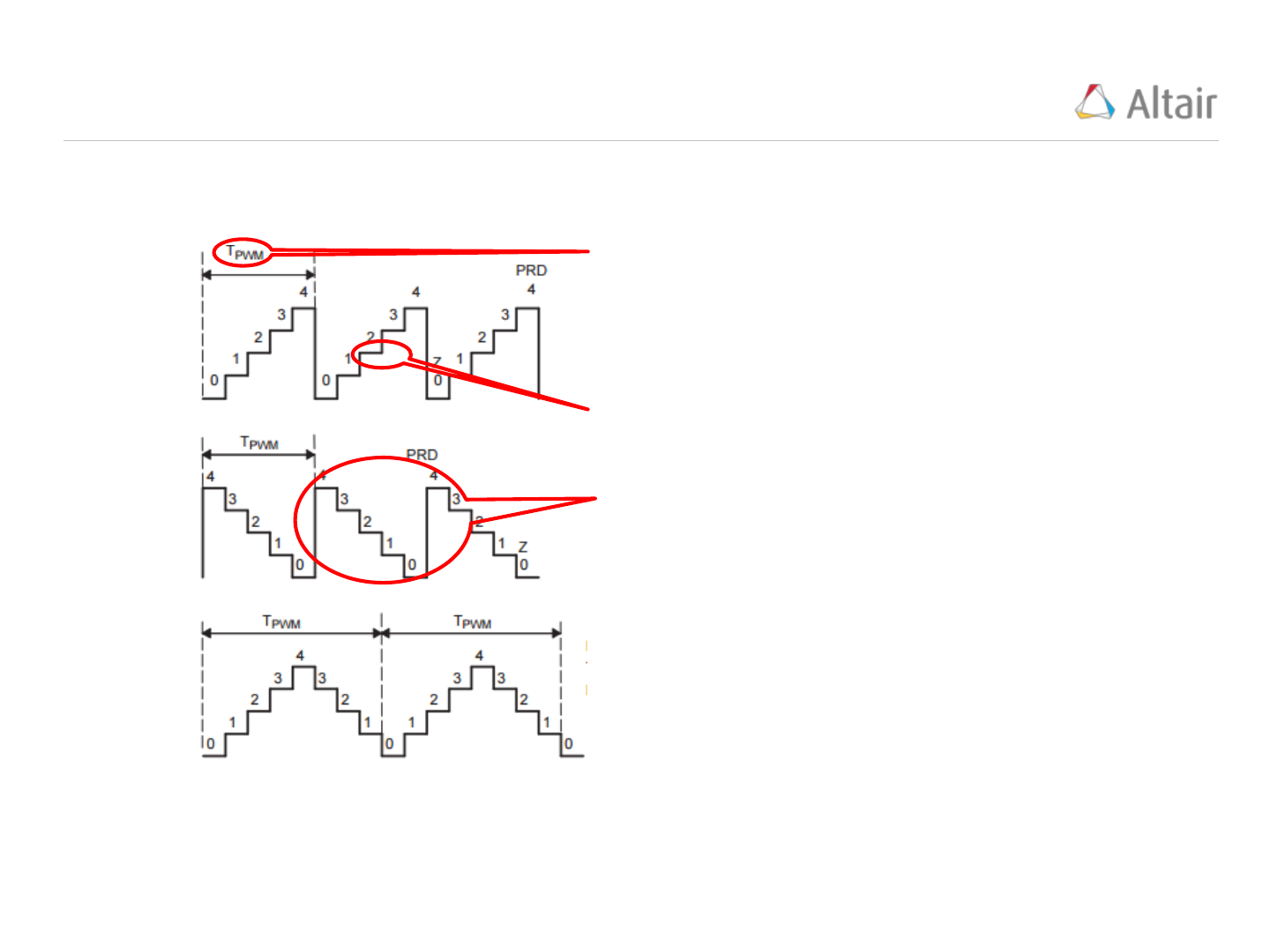

Most target processors support three Count Modes; Up Count, Down Count, and Up/Down Count:

Up

Count

Mode:

Down

Count

Mode:

Up/Down

Count

Mode:

Tpwm is the PWM

Carrier Period (sec),

Fpwm is the PWM

Carrier Frequency

(Hz).

Tpwm is approx.

twice the value for

the Up/Down

Count Mode

compared with the

Up or Down Count

Modes

Each step occurs at

a clock tick.

Timer Period is the

number of steps in

one Carrier Period

Tpwm = (TBPRD + 1) * TBCLK

Tpwm = 2*TBPRD* TBCLK

Tpwm = (TBPRD + 1) * TBCLK

Fpwm = 1/Tpwm

Fpwm = 1/Tpwm

Fpwm = 1/Tpwm

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Resolution

6

The resolution, n, of a PWM generator is equal to the number of Time Based pulses present in the

PWM period expressed as a number of bits.

Resolution expressed as a number of bits:

Number of Time Base pulses per PWM period =

For example, a 20kHz PWM signal is to be generated using an 80MHz CPU. The Time Based Clock

(TBCLK) is set to 1/80Mhz and the resolution is calculated as:

The High Resolution Timer option, if available on your hardware, decreases the TBCLK to a value of

150e-12 seconds. This is particularly useful if your application requires a high PWM frequency

(NOTE: 250kHz and greater is considered to be a high PWM frequency).

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

DCB

DCA

VisSim ePWM Block

7

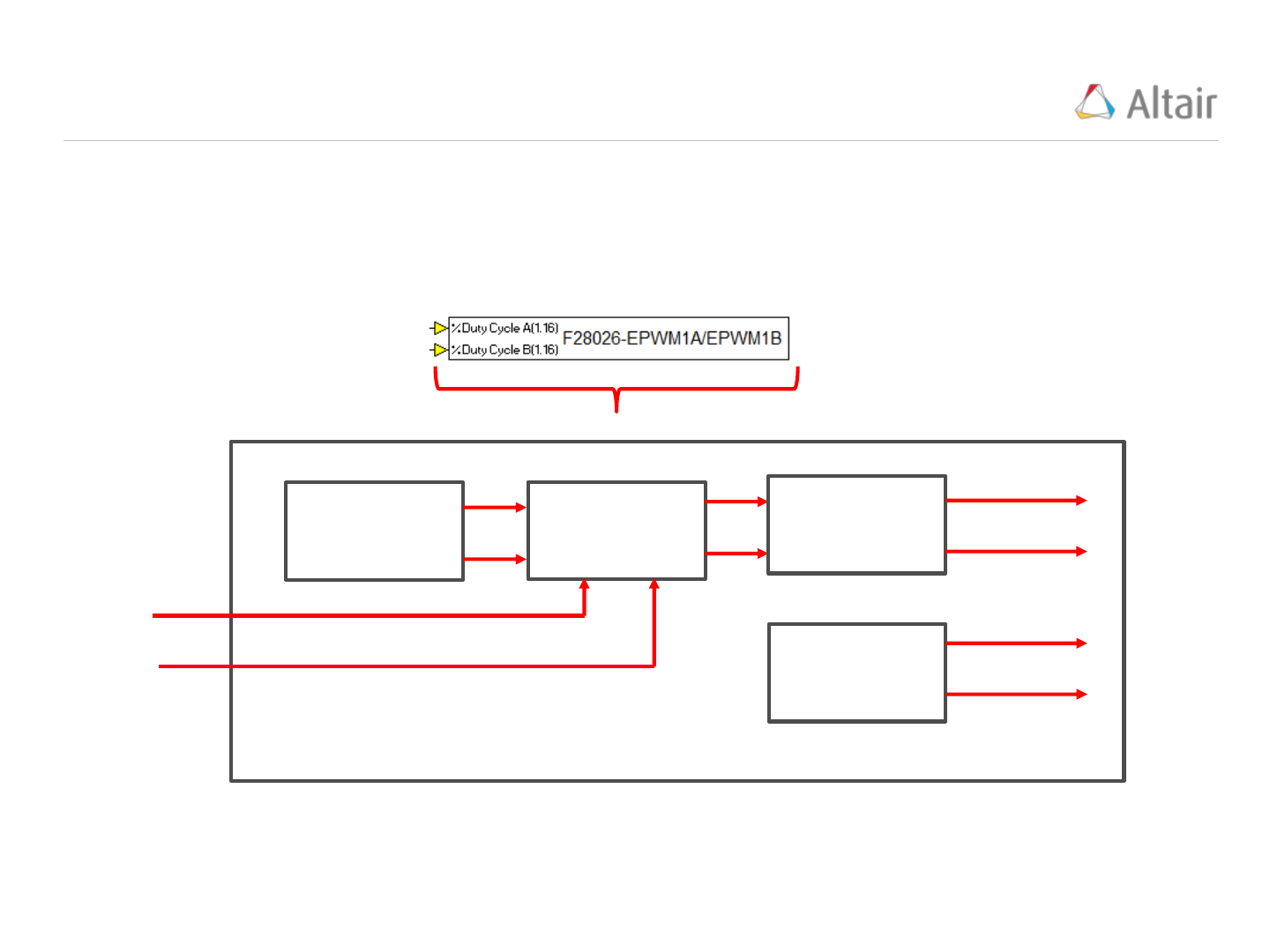

The VisSim ePWM block (below) is a two channel device. It has two Duty Cycle (DC) inputs and

produces two PWM output signals and two Start of Conversion (SOC) signals. The channels are

referred to as “A” and “B”. The DC inputs are fractions in 1.16 format. The PWM and SOC signals are

sent directly to hardware pins. They are accessible to your VisSim model using an “Extern Read”

statement.

SOCA

PWMB

PWMA

SOCB

Action Qualifier

Module

Deadband

Module

Time Based

Module

Event Time

Module

The ePWM block consists of four key Modules; (1) Time Based, (2) Action Qualifier, (3) Deadband,

and (4) Event Timer. Each Module is described in this document.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

VisSim PWM Block – Module Properties

8

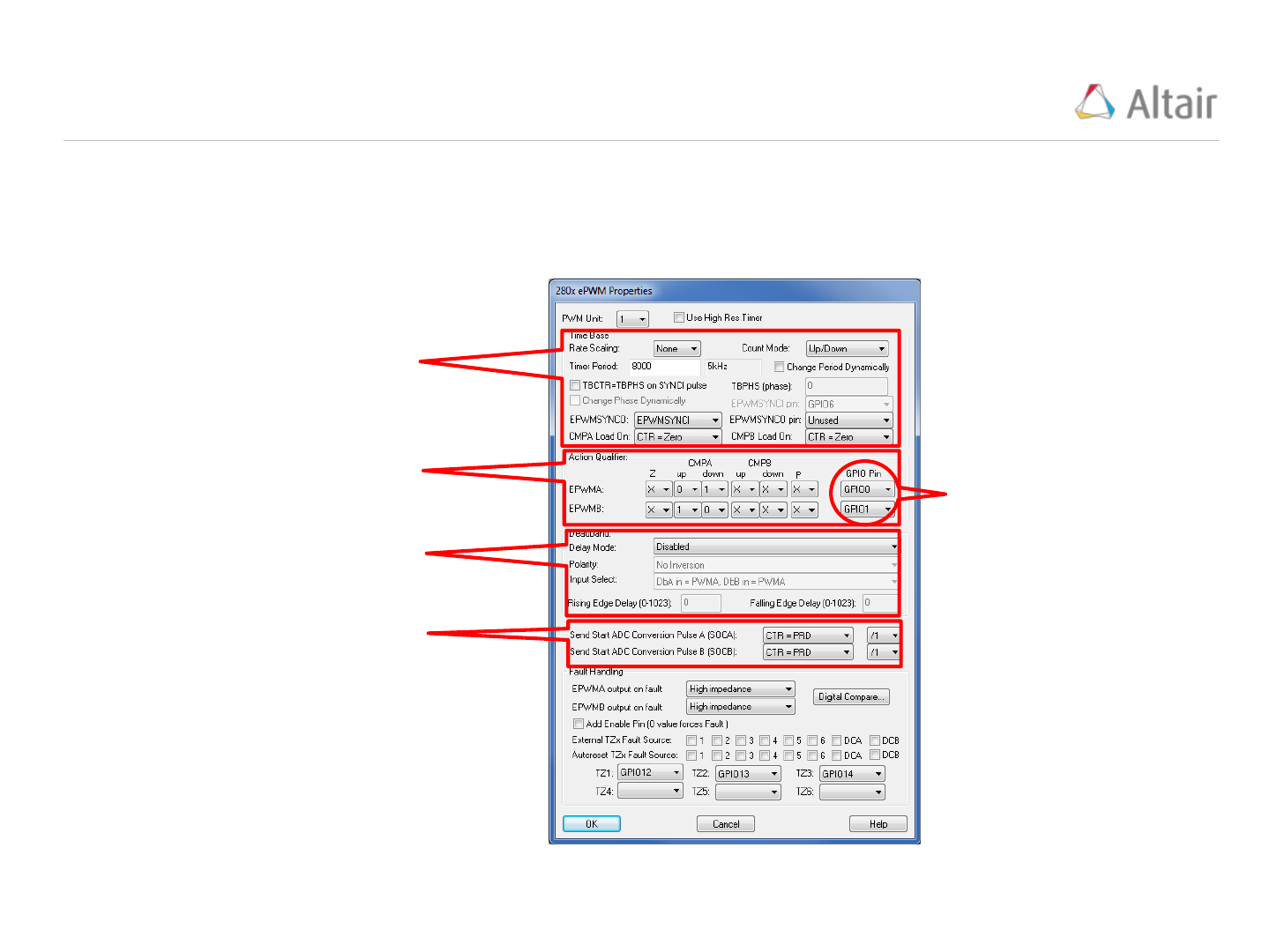

The VisSim ePWM block (“Embedded/Piccolo/ePWM”) property window is used to configure the PWM

Modules.

Time Base Module: Define the type of

count and Period

Action Qualifier Module: Define when the

PWM cycles and the PWM output Pin

Deadband Module: Define deadband to

prevent “shoot-through” and polarity

PWM Output Registers

Event Time Module: Define the SOC

signals

SOC Outputs

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

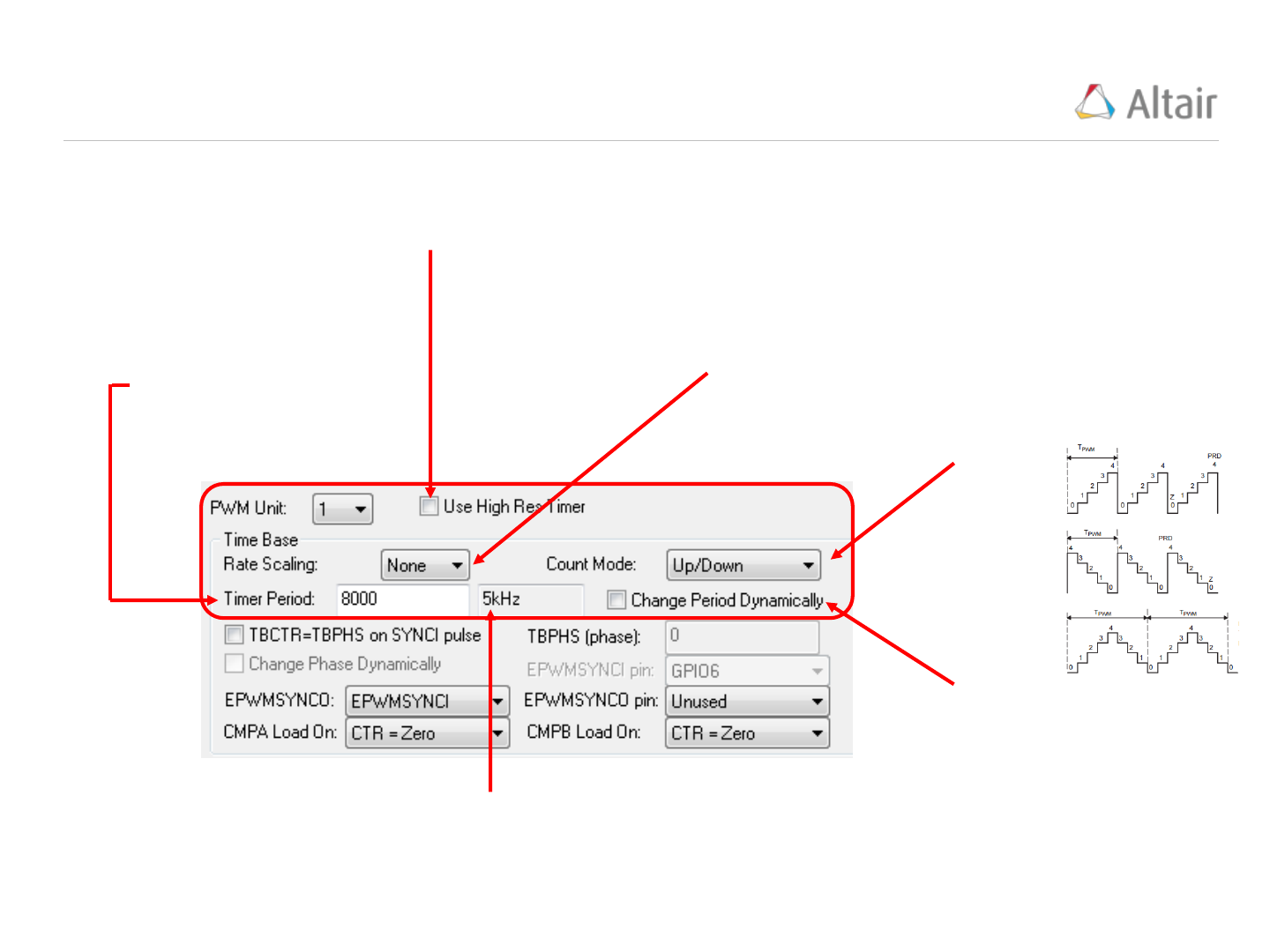

VisSim ePWM – Basic Time Base Module Configuration:

9

User select: Set the

TBPRD = # clock ticks

per PWM period.

VisSim calculates the PWM Carrier frequency

(Fpwm) based on the Timer Period, Count Mode,

and Rate Scaling.

3 Count

Modes:

Sets the TBCLK = k/CPU clock speed

(Hz), where k is selected from the

dropdown menu. Note: “None” means

k=1.

The basic “Time Base” Module features of the ePWM (“Embedded/F280x”) block are located in the

“Time Base” frame of the ePWM properties window.

Explained on the

next slide

Sets the TBCLK = 150e-12 seconds (approximately) for high

frequency PWM applications (typically > 250kHz)

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

Change Period Dynamically Option

10

Based on the ON and OFF times selected, the PWM Period is calculated as 500nsec and the PWM

Carrier Frequency is calculated as 1/500nsec = 2MHz.

In some situations it is not possible to create the desired PWM Carrier Frequency from the integer “Timer

Period”. Suppose we wanted to create a PWM signal with a minimum 25nsec ON time and 475nsec OFF

time. The “Count Mode” is set to “Up/Down”. The CPU Speed is 90MHz and the TBCLK = 1/90MHz.

Since the “Timer Period” MUST be an integer

value, it is not possible to achieve the desired

2MHz PWM Carrier Frequency. (Here the best

we can do is set “Timer Period” = 2 to achieve

2.04545MHz)

To solve this problem, select the “Change Period Dynamically” option which adds a “Period(1,16)”

input pin to the PWM block. This pin accepts a user defined “Fractional Period Multiplier”

constant that is calculated as follows:

After some experimentation adjusting the “Timer

Period” value, we select a value of 200 which

produces a PWM Carrier Frequency of 225kHz.

Since 225k/2M = .1125 is a rational fraction

between 0 and 1, we will use this “Timer Period”

value and a “Fractional Period Multiplier” set to

.1125 to achieve the 2MHz PWM Carrier

Frequency.

Experiment with the “Timer Period” value until you obtain a value that produces a PWM Carrier

Frequency, F, such that F/2MHz is a rational fraction between 0 and 1 (Note: 2MHz is the desired

PWM Carrier Frequency). The “Fractional Period Multiplier” is set to this rational fraction.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Frequency Selection Issues:

11

Interference with Mechanical System Frequency: Generally dominant mechanical frequencies are in the

200Hz or less range. PWM frequency should be selected at least 10x the dominant mechanical

frequency. This is normally not a limiting factor.

Power Loss: In a motor, torque is proportional to the average current. Consider a motor with a torque

constant k driven by a constant current source,

and by a PWM current source that ranges from 0 to

and has a Duty Cycle, DC. To achieve the same torque, the following is true:

The PWM driven motor requires

more current than the constant

current motor to develop the

same torque.

Heat: In a motor winding there is always a small resistance, R. As current is passed through

the winding resistance,

watts of energy is transferred from electrical to heat energy. For

a PWM current signal with a period, T, on-time, tOn, Duty Cycle, DC, and ranging from 0 to

, the

value is calculated as:

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Frequency Selection Issues:

12

For a 0 to

PWM signal, power loss through a resistor, R, is calculated as:

For a constant current signal of value

, power loss through R is:

As DC decreases, more and more power is lost through the

resistance to heat when using a PWM signal compared to a

constant signal of the same average value.

Switching Losses: An ideal switch is either fully on or off which means it never dissipates any power.

Real switches don’t switch instantaneously, they have a transition time during which they dissipate power.

The transition time is usually fixed per edge. For example, using a switch that requires a 1 microsecond

transition time in a 25kHz PWM (40 microsecond period) means that the transition time is 1/40 of the

total. If the PWM frequency were increased to 250kHz (4 microseconds), this ratio would increase to ¼

which would significantly and adversely affect performance.

Vibration and Noise: An electric motor uses wire coils to produce magnetic force. Every length of wire

in the motor undergoes lateral movement proportional to the current being passed through it. When the

current is cycled, i.e. a PWM signal, the movement becomes a regular vibration audible to the human

ear. Since the range of human hearing is generally considered to be 20Hz to 20kHz, PWM frequency is

often selected to be 20kHz or greater to eliminate audible noise being produced.

Resolution: Normally a resolution of 10 bits (1/1024 = .001) is adequate. Based on your CPU speed

and PWM period, confirm your resolution is adequate. If not consider using the “High Resolution Timer”,

adjusting the PWM period, overclocking, or moving to a faster CPU.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

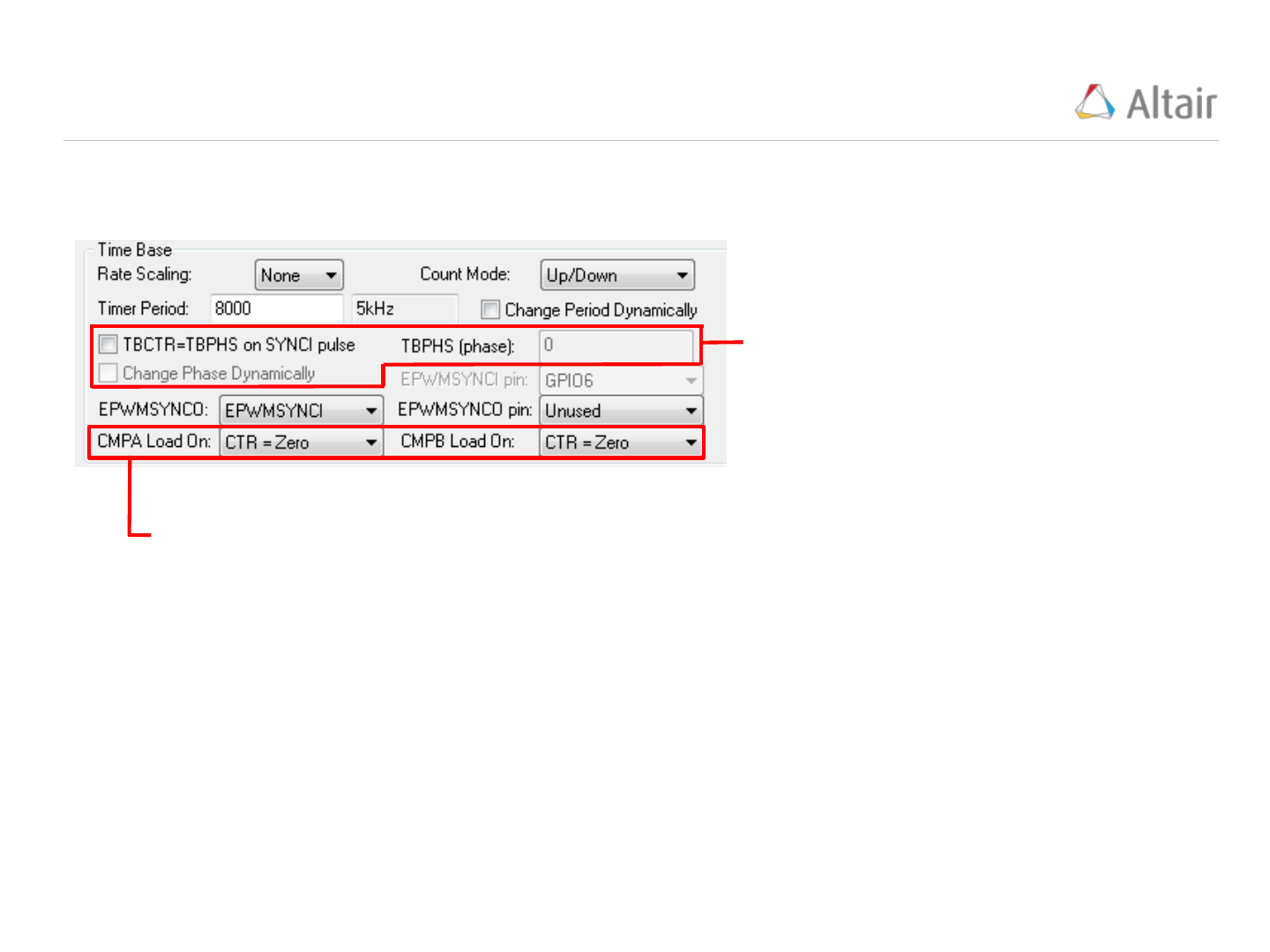

Advanced Time Base Module Configuration:

13

TBPHS: is a count offset value (to produce

a phase shift)

TBCTR = TBPHS on SYNC1 pulse: When

checked, the TBPHS count offset value is

added to TBCTR when a SYNC1 pulse

occurs.

Change Phase Dynamically: Adds an input

pin to the PWM block which accepts a

fractional value that is multiplied by the

“Timer Period” and assigned to “TBPHS”.

The advanced “Time Base” Module features of the ePWM (“Embedded/F280x”) block are located in the

“Time Base” frame of the ePWM properties window

Specify the condition when to load the CMPA and

CMPB values. Choices are [Zero, Period, Period

or Zero, and Immediate]. Normally “Zero” is

selected.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

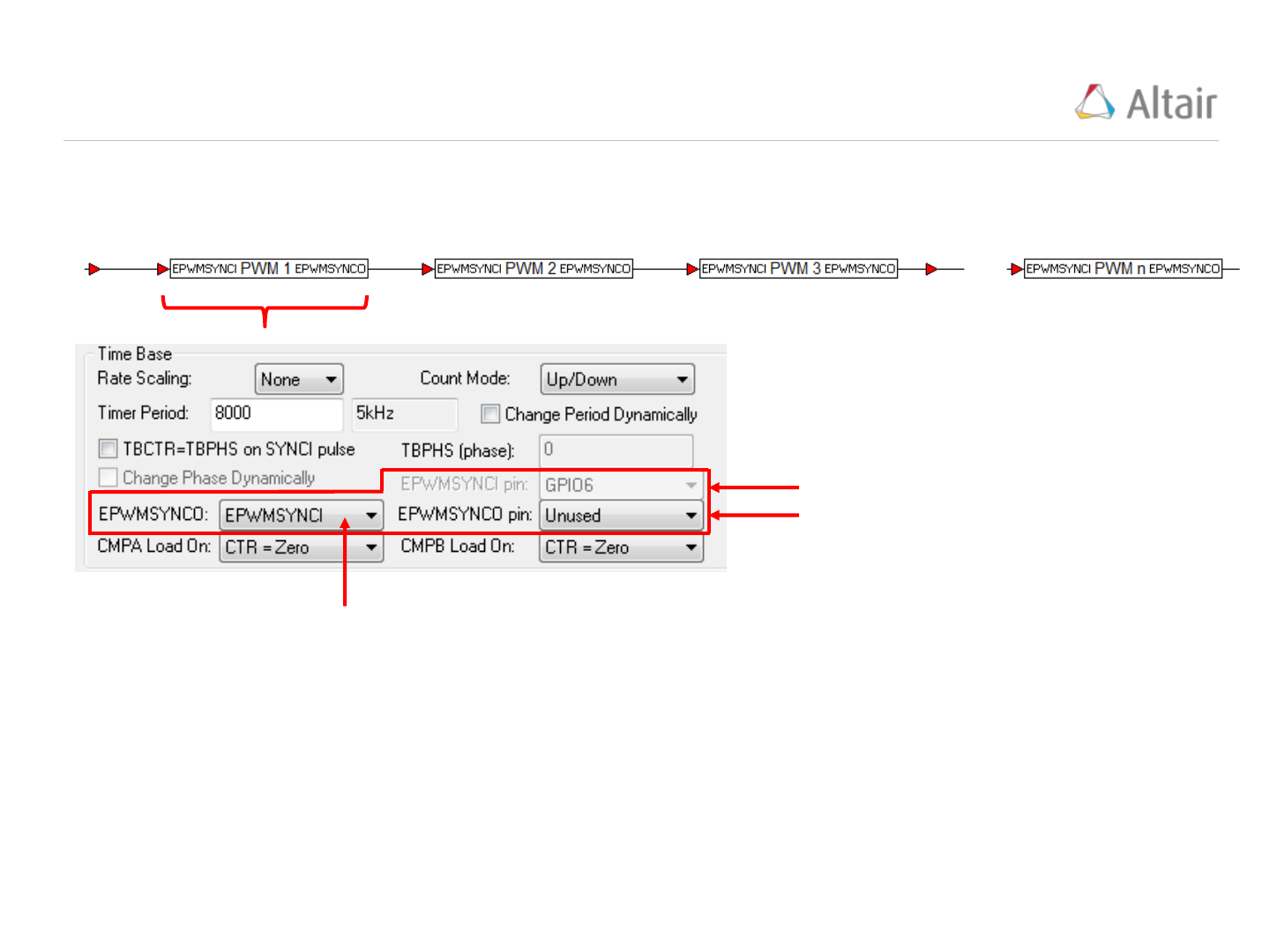

Advanced Time Base Module Configuration -

Synchronization:

14

The operation of PWM modules can be synchronized to operate as a single system when needed using

hardware pins named EPWMSYNCI (input) and EPWMSYNCO (output).

There are 4 selectable synchronizing actions that can be applied to the

EPWMSYNCO output signal:

EPWMSYNCI: This sets EPWMSYNCO = EPWMSYNCI

TBCTR = zero: This sets EPWMSYNCO = 1 when the TBCTR (time based

counter) = 0

TBCTR = CMPB: This sets EPWMSYNCO = 1 when the TBCTR = CMPB

None: This sets EPWMSYNCO =0 always

…

Input pin

Output pin

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

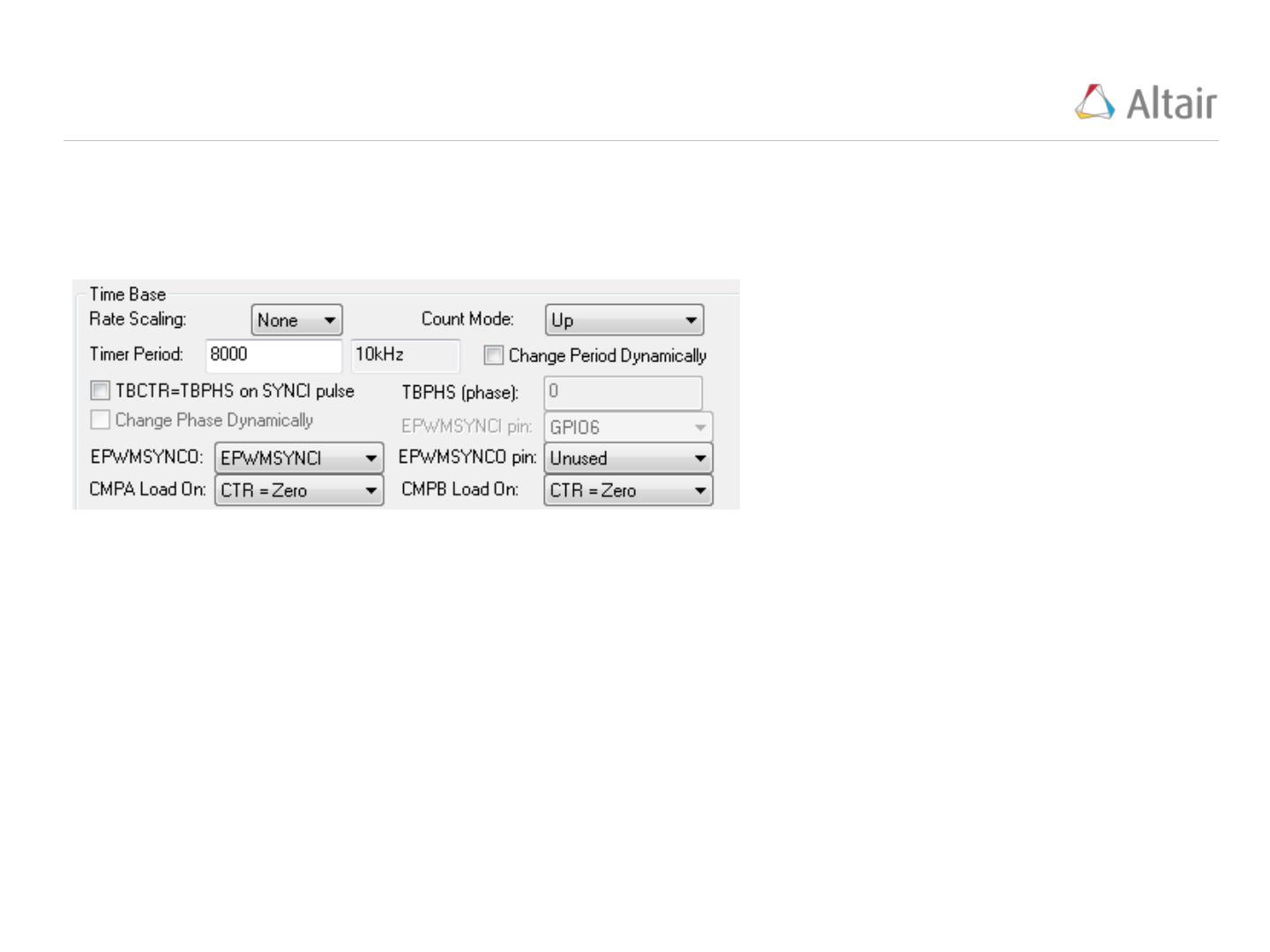

VisSim PWM – Time Base Setup Example 1

15

Example 1:

Setup the PWM to produce a 10kHz carrier frequency with “Count Mode” set to “Up. The CPU Speed

is 80MHz.

Step 1: Experiment with “Timer Period” until 10kHz Carrier Frequency is

obtained.

NOTE: CPU Speed = Timer Period * Carrier Frequency

NOTE: there are 8000 discrete levels of duty cycle in this configuration

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

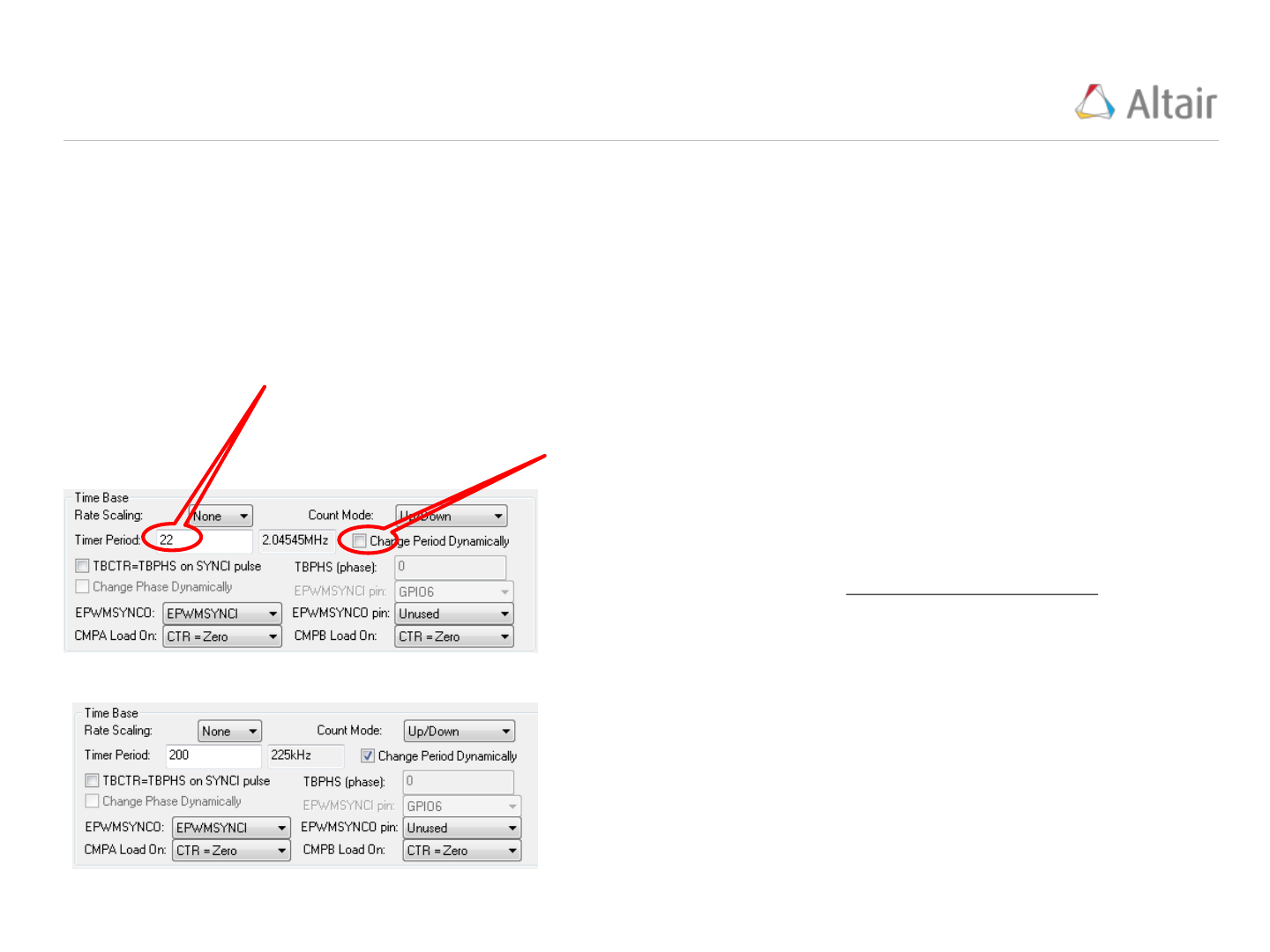

VisSim PWM – Time Base Setup Example 2 (1/3)

16

Based on the ON and OFF times provided, the Carrier Period is calculated as 500nsec OR equivalently,

the Carrier Frequency is 2MHz.

Example 2:

Setup the PWM to produce a 25nsec ON and 475nsec OFF signal with “Count Mode” set to

“Up/Down”. The CPU Speed is 90MHz.

“Timer Period” MUST be an integer

value, we cannot achieve the desired

2MHz Carrier Frequency.

To solve this problem, use the “Change Period Dynamically” option

which allows you to define a “Fractional Period Multiplier” and send to

the “ePWM” block through the “Period” input pin.

Operation:

New Carrier Frequency =

New Timer Period =

Setting the “Fractional Period Multiplier” = .1125, these settings

become:

New Carrier Frequency = 225kHz/.1125 = 2MHz

New Timer Period = 200 * .1125 = 22.5

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

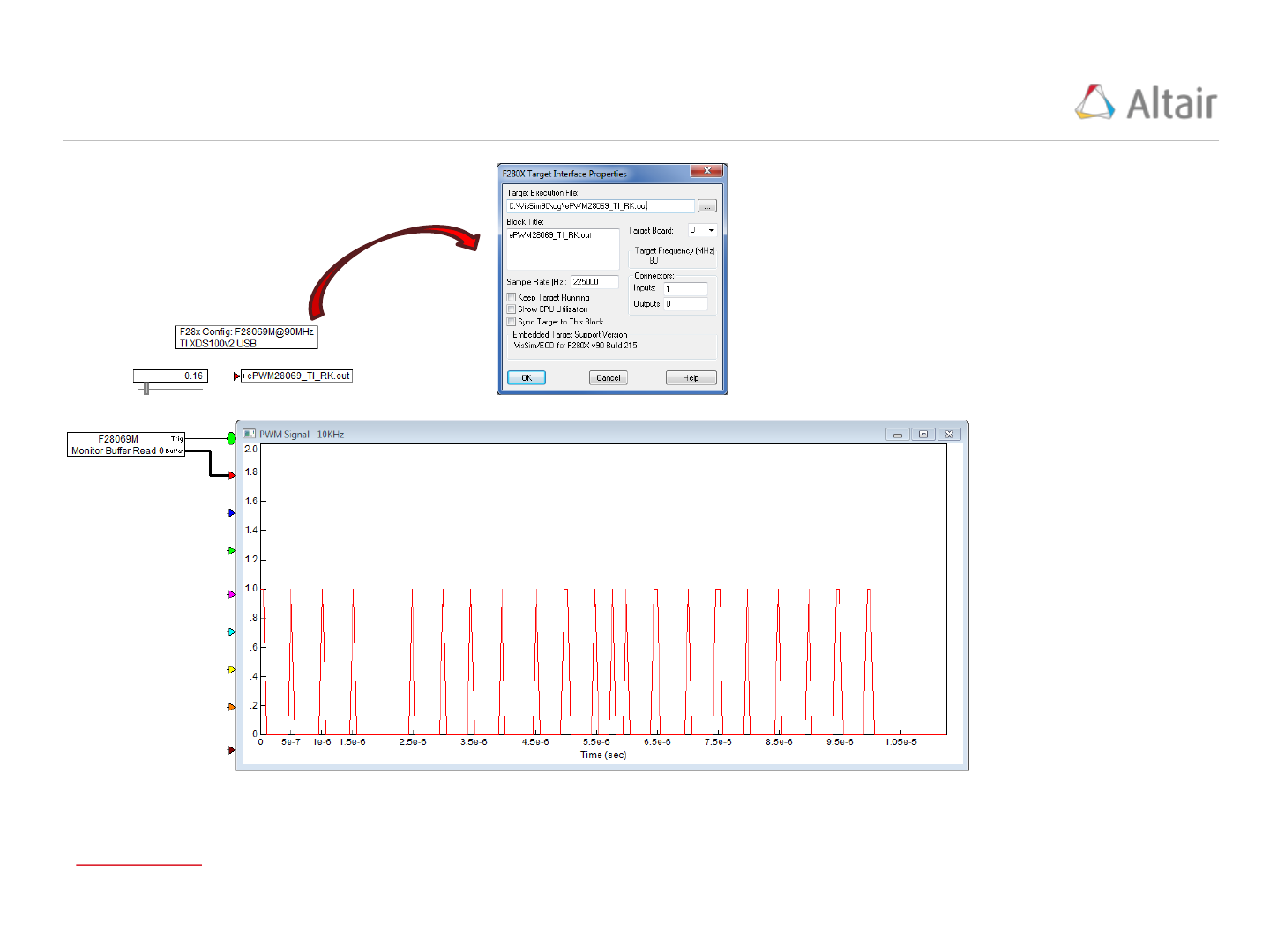

VisSim PWM – Time Base Setup Example 2 (3/3)

18

Debug Model:

Debug Model

Plot x-Range Calculation:

200 points are recorded in the buffer.

PWM frequency = 2MHz = 500nsec

Fractional Period Multiplier = .1125

xMax = 200 * 500e-9 * .1125 = 1.125e-5 seconds

Simulation Setup:

TimeStep = .01 seconds

End = 20 seconds

Sample Rate = 225kHz

NOTE: the actual sample rate is 225kHz/.1125 =

2MHz

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Events & Actions

19

time

TBCTR

(counts)

CMP value

5

4

3

2

1

0

TBPRD value

Zero (Z) Event:

TBCTR = 0

Up Event:

TBCTR = CMP while increasing

Period (P) Event:

TBCTR = TBPRD

Down Event:

TBCTR = CMP while decreasing

At each Event, any of four Actions can be performed. These actions provide a means to define the

PWM edges:

X = Do Nothing

0 = Force the PWM value to 0 (Off Value)

1 = Force the PWM value to 1 (On Value)

T = Toggle the PWM value

if the PWM value = 1, Toggle will set it = 0 and if the PWM value = 0, Toggle will set it = 1

The Duty Cycle input value is

converted to a CMP value.

As the TBCTR pulse counter

increments from 0 to TBPRD,

it passes through the CMP

value.

Similarly, when the TBCTR is

reset to 0, it also passes

through the CMP value.

These four Events, Z, Up,

Down, and Period are shown

(right):

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

VisSim ePWM – Action Qualifier Module

20

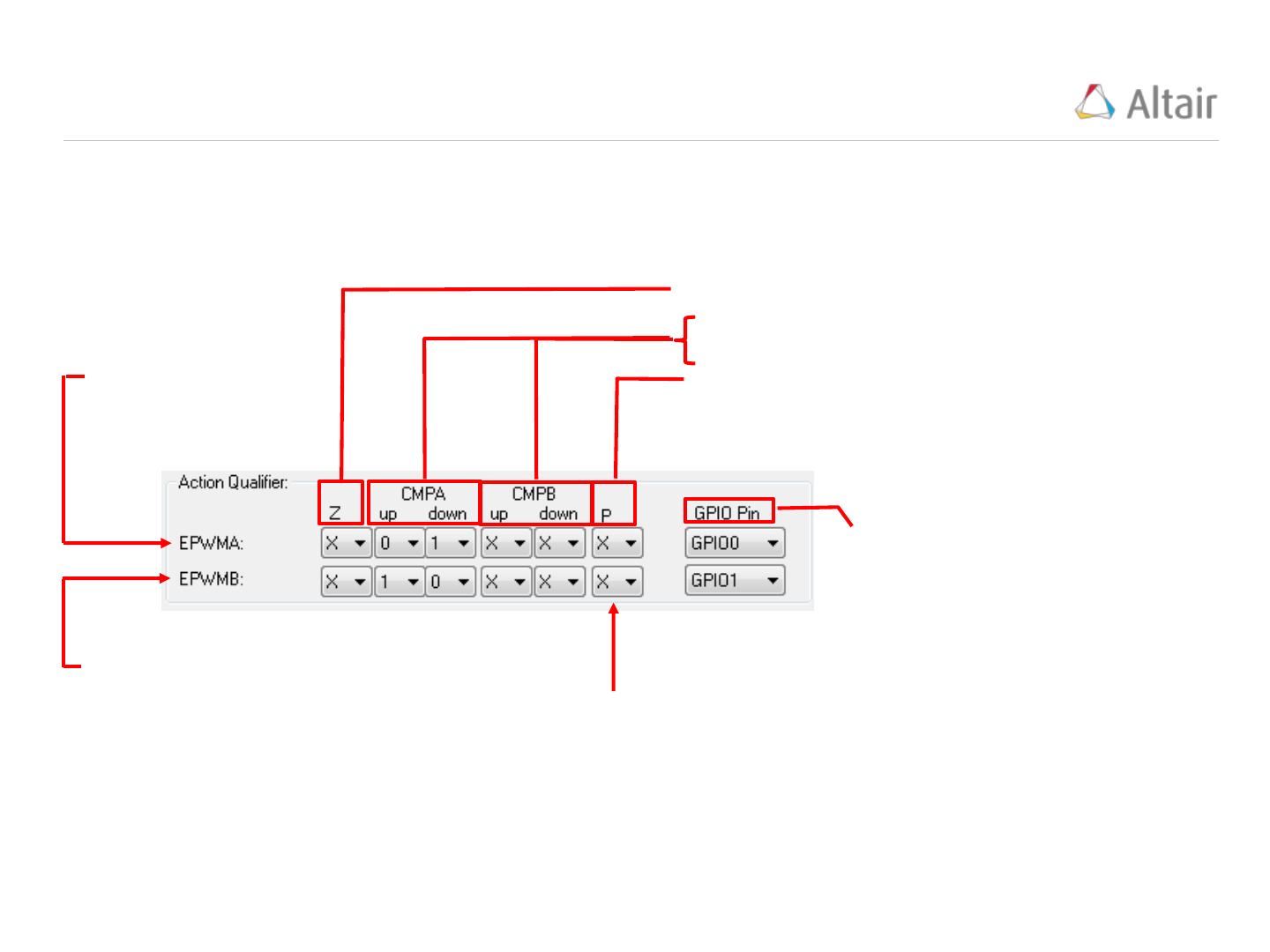

The “Action Qualifier” Module features (Events, Actions, and PWMA and PWMB output pins) are

configured “Action Qualifier” frame of the ePWM properties window.

User select: Action dropdown:

X = Do Nothing

0 = Force PWM output to 0

1 = Force PWM output to 1

T = Toggle PWM output

Events:

Z = When TBCTR = 0

up = When TBCTR = CMP while increasing

down = When TBCTR = CMP while decreasing

P = When TBCTR = TBPRD

Output Pin numbers

assigned to PWMA and

PWMB.

PWMA Action,

Event, & Pin

Settings

PWMB Action,

Event, & Pin

Settings

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

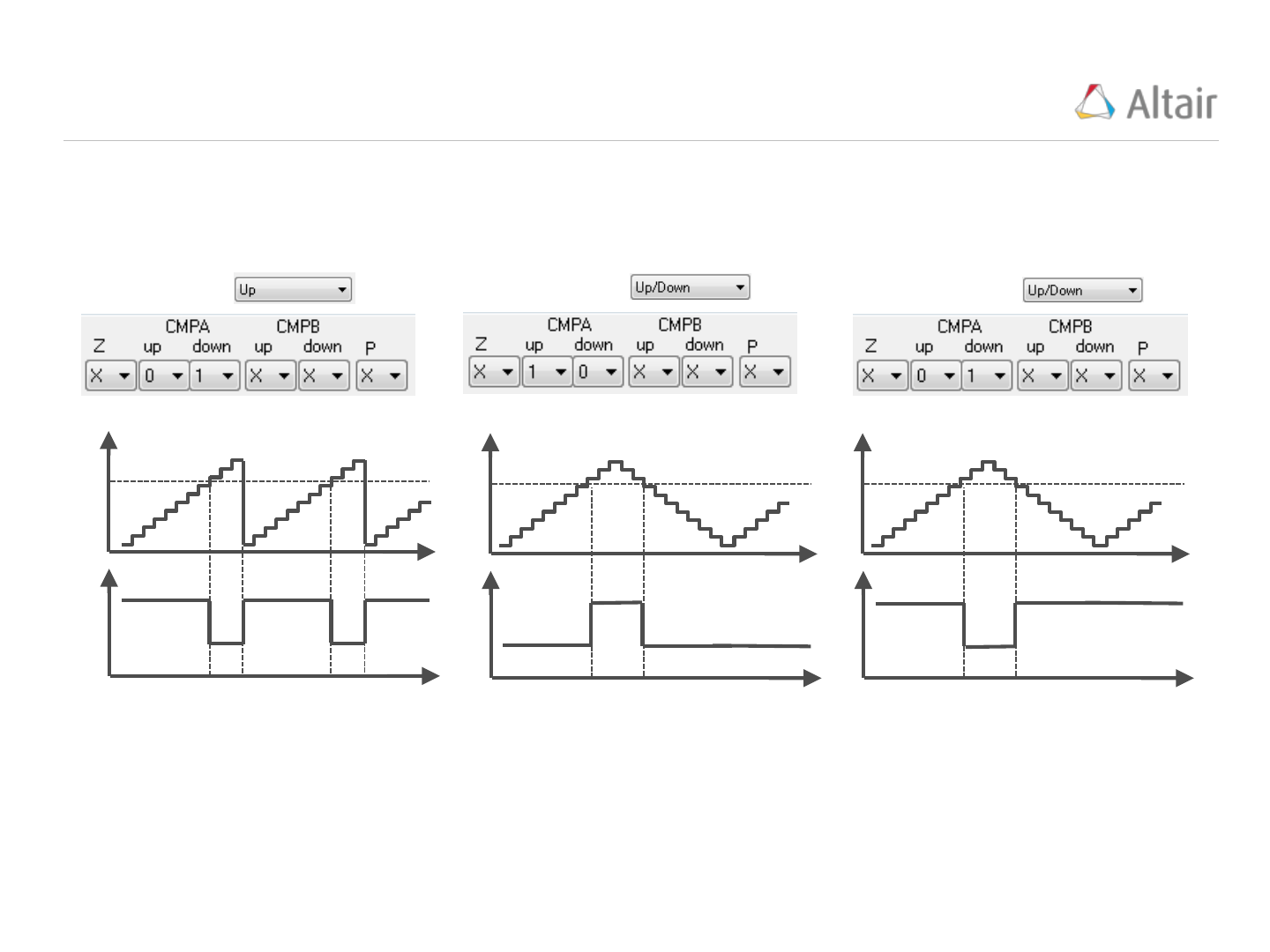

PWM Examples

21

Count Mode

Example 1

Count Mode

Count Mode

Example 2 Example 3

CMP

value

TBCTR

PWM

time

time

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

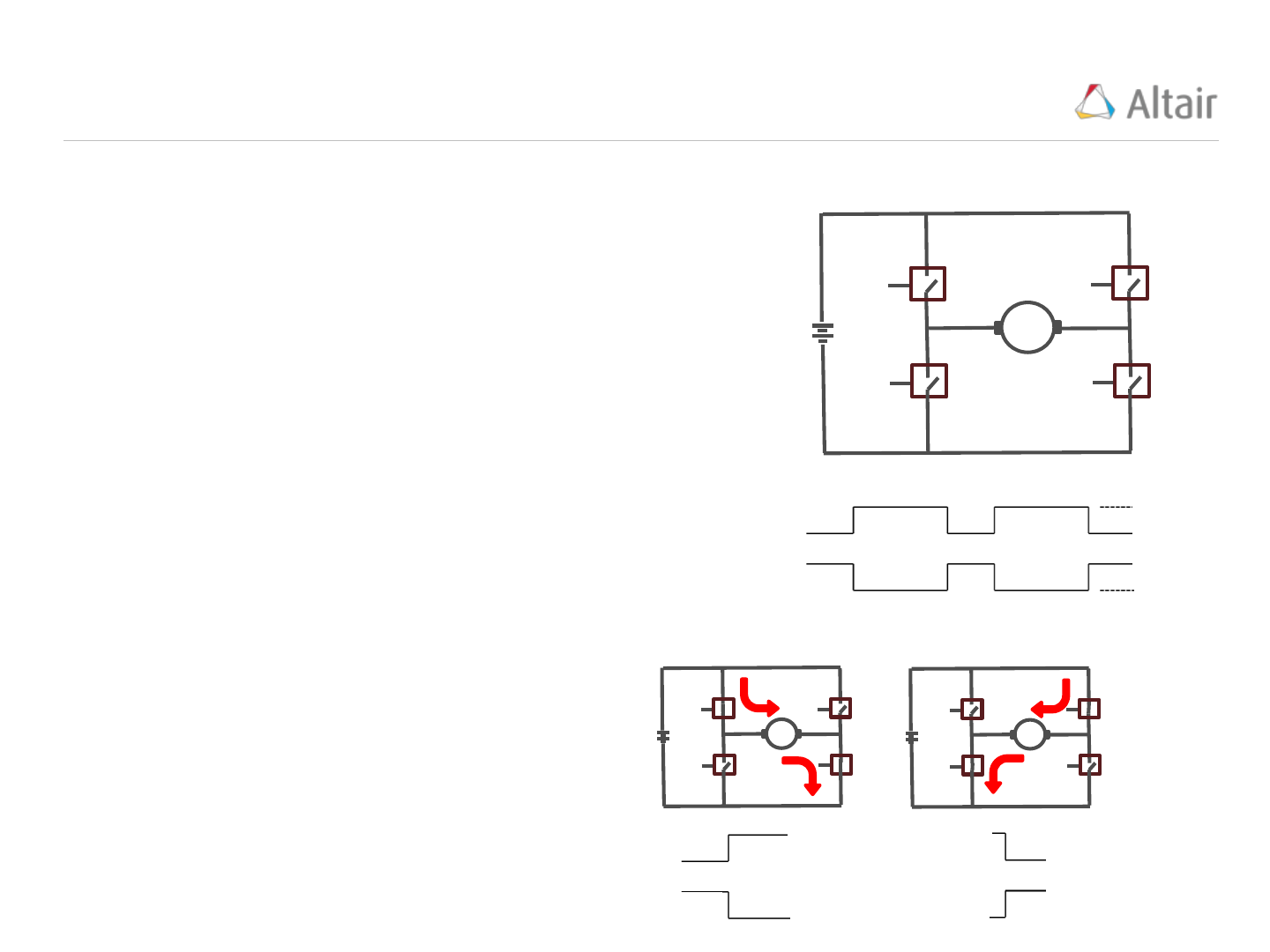

PWM Deadband

22

An H bridge is an electronic circuit consisting of 4 switches. One use of an H bridge is to provide

bidirectional rotation control of a DC motor.

When switches S1 and S4 are closed (and S2 and S3

are open) a positive voltage is applied across the motor

(M) causing it to rotate in one direction. Closing S3 and

S2 and opening S1 and S4 reverses the voltage polarity

across the motor causing it to operate in the reverse

direction.

S1

S2

S3

S4

+

Vdc

-

M

The four switches are controlled by a complimentary

pair of PWM signals, PWMA and PWMB. PWMA

controls S1 and S4 and PWMB controls S2 and S3. An

ideal pair of PWM control signals is shown to the right:

Closed

PWMA

PWMB

Closed

Open

Open

Ideal switches require 0 time to switch

between states (Open and Closed). If

the switches are ideal, two current flow

patterns are possible:

Closed

PWMA

PWMB

Closed

Open

Open

PWMA

PWMB

S1

S2

S3

S4

S1

S2

S3

S4

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

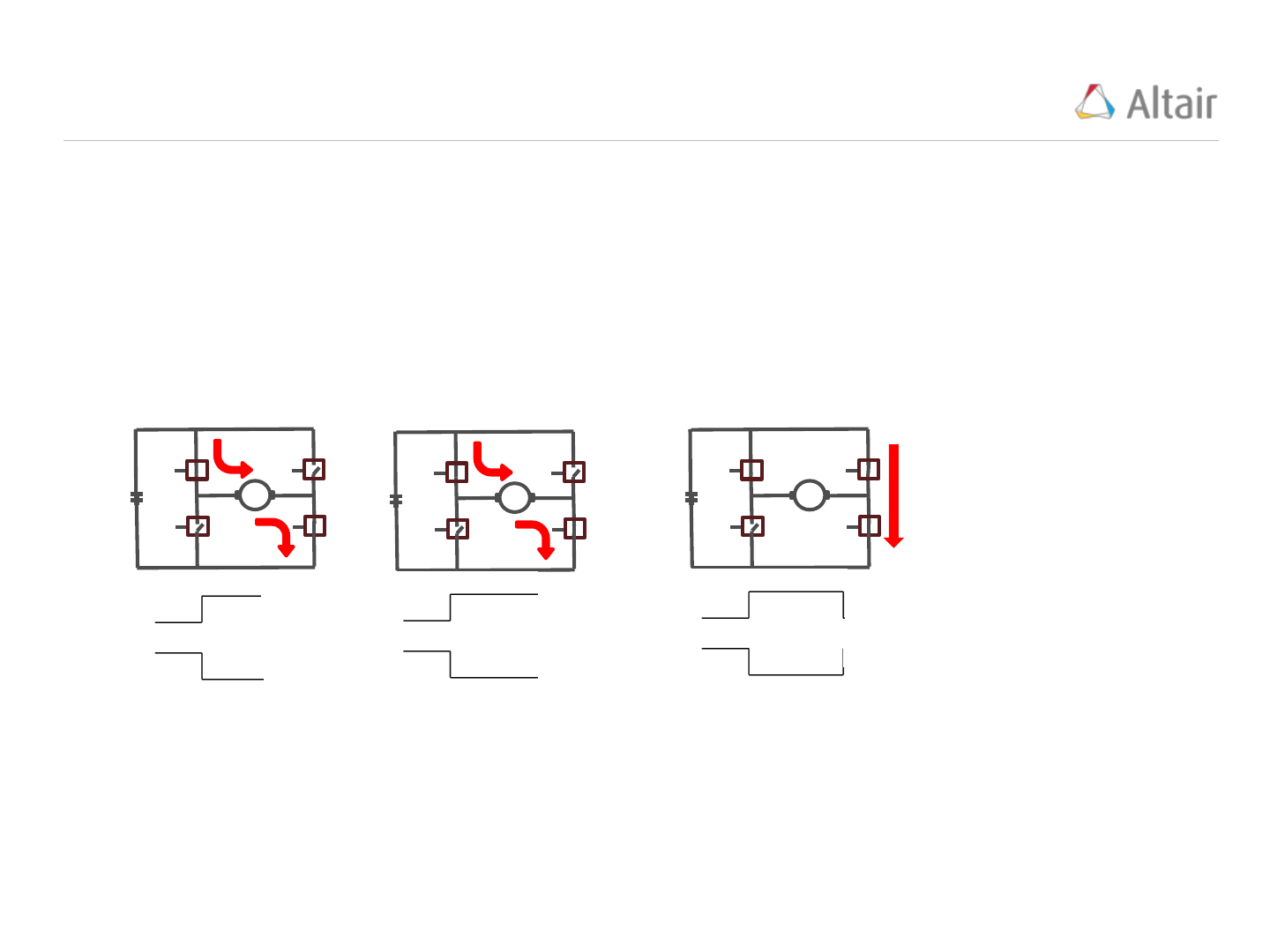

PWM Deadband – Shoot Through

23

PWMA commanded S1

and S4 to Open but

due to their longer

switch “turn Off” times,

they remain closed

while S3 (commanded

by PWMB) closes

because of it’s shorter

“turn On” time*.

Real switches (Thyristors, FET’s, …) do not behave in an ideal manner. They have a finite “turn On” and

“turn Off” switch transition time which, in general, are not equal. When these switches are used in an H

bridge under PWM control, these transition times can cause a catastrophic failure of the switches called

“Shoot Through”. For example, a thyristor application may have a “turn On” = .2 milliseconds and “turn

Off” = 2.8 milliseconds.

In the following sequence of switch conditions, PWMA transitions from ON (Closed) to OFF (Open) and

PWMB from OFF to ON. The sequence uses non-ideal switches, each with a “turn Off” time > “turn On”

time.

Closed

PWMA

PWMB

Open

Closed

PWMA

PWMB

Open

Closed

PWMA

PWMB

Open

S1

S2

S3

S4

S1

S2

S3

S4

S1

S2

S3

S4

PWM signal generators have a feature called “Deadband” which provides a method for independently

adding delay to the PWMA and PWMB edges (both rising and falling edges) to accommodate switch

transition times and prevent a Shoot Through situation from occurring.

* S2 was excluded in this explanation for clarity, it too could be in a closed state.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWMB

PWMA

DbB

DbA

PWMB

PWMA

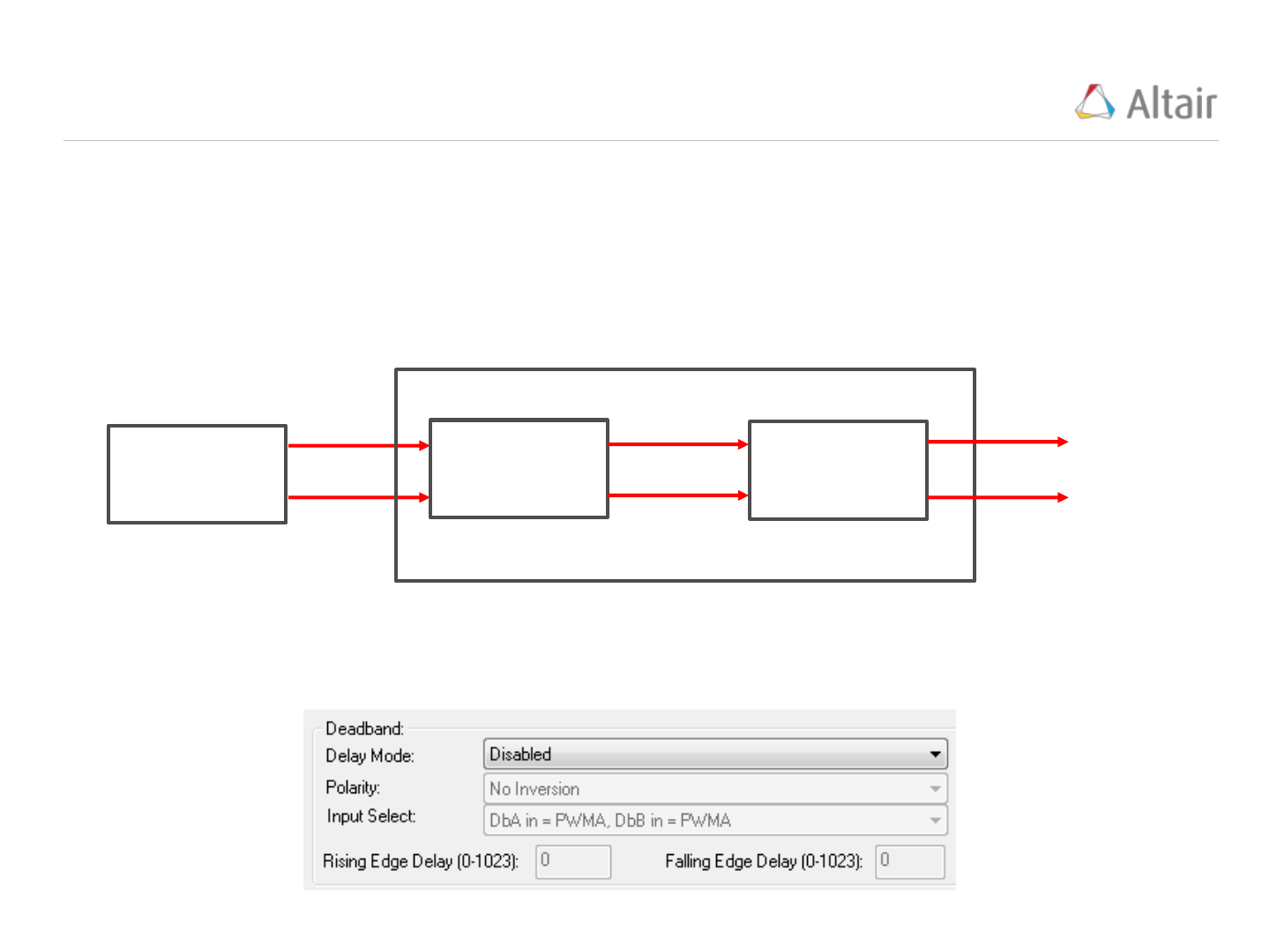

VisSim ePWM – Deadband Module

24

The “Deadband” Module allows delays to be added to rising and/or falling edges of the PWM signals.

The input signals to the “Deadband” module are the PWMA and PWMB output signals from the “Action

Qualifier” module. Internally, the “Deadband” module creates the signals “DbA” and “DbB” for channel

A and B based on the “Input Select” settings. The “Delay Mode” and “Polarity” settings are then

applied to the “DbA” and “DbB” signals to produce the PWMA and PWMB output signals (below):

Action Qualifier

Module

Deadband Module

Input Select

Delay Mode

And Polarity

The “Deadband” Module of the ePWM (“Embedded/F280x”) block is located in the "Deadband" frame

of the ePWM properties window.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

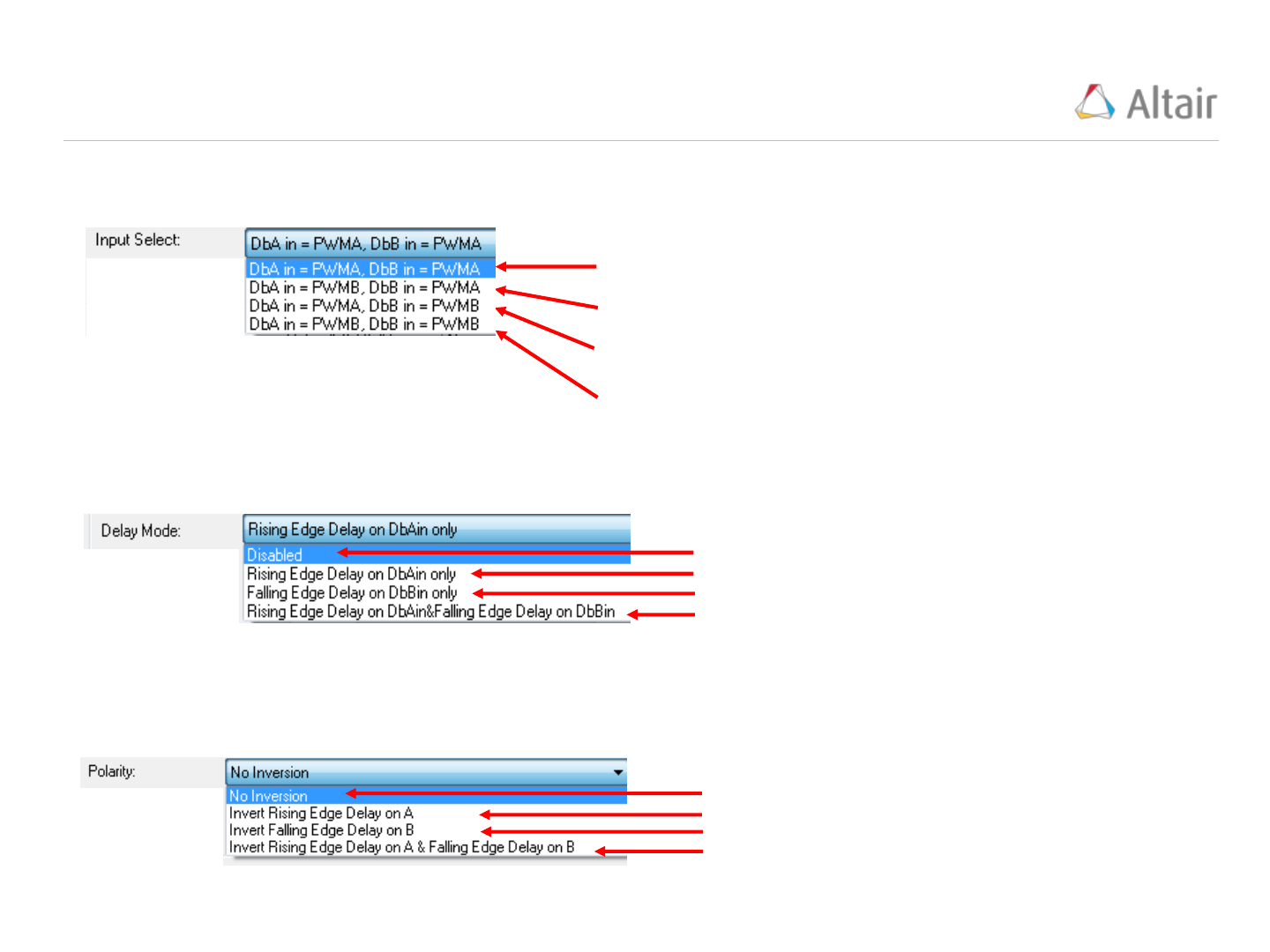

VisSim ePWM – Deadband Module

25

• Off

• Deadband is applied to PWMA rising edge

• Deadband is applied to PWMB falling edge

• Deadband is applied to PWMA rising edge and

PWMB falling edge

Delay Mode: Specifies the PWM Deadband mode to be used for Deadband operations, there

are four options:

• Off

• Invert rising edge delay on PWMA

• Invert falling edge delay on PWMB

• Invert rising edge delay on PWMA and invert falling

edge delay on PWMB

Polarity: The polarity control allows you to specify whether the rising-edge delayed signal and/or the

falling-edge delayed signal is to be inverted before being sent out of the Deadband module. There are

four options

• PWMA In is the source for both falling-edge and rising-edge

delay. This is the default mode.

• PWMA In is the source for falling-edge delay, PWMB In is the

source for rising-edge delay.

• PWMA In is the source for rising edge delay, PWMB In is the

source for falling-edge delay.

• PWMB In is the source for both falling-edge and rising-edge

delay.

Input Select: Specifies the PWM source signals to be used for ChA and ChB deadband operations.

These signals are named “DbA” and “DbB”. Four configuration options are available

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

200 counts

100 counts

DbA

DbB

PWMB

PWMA

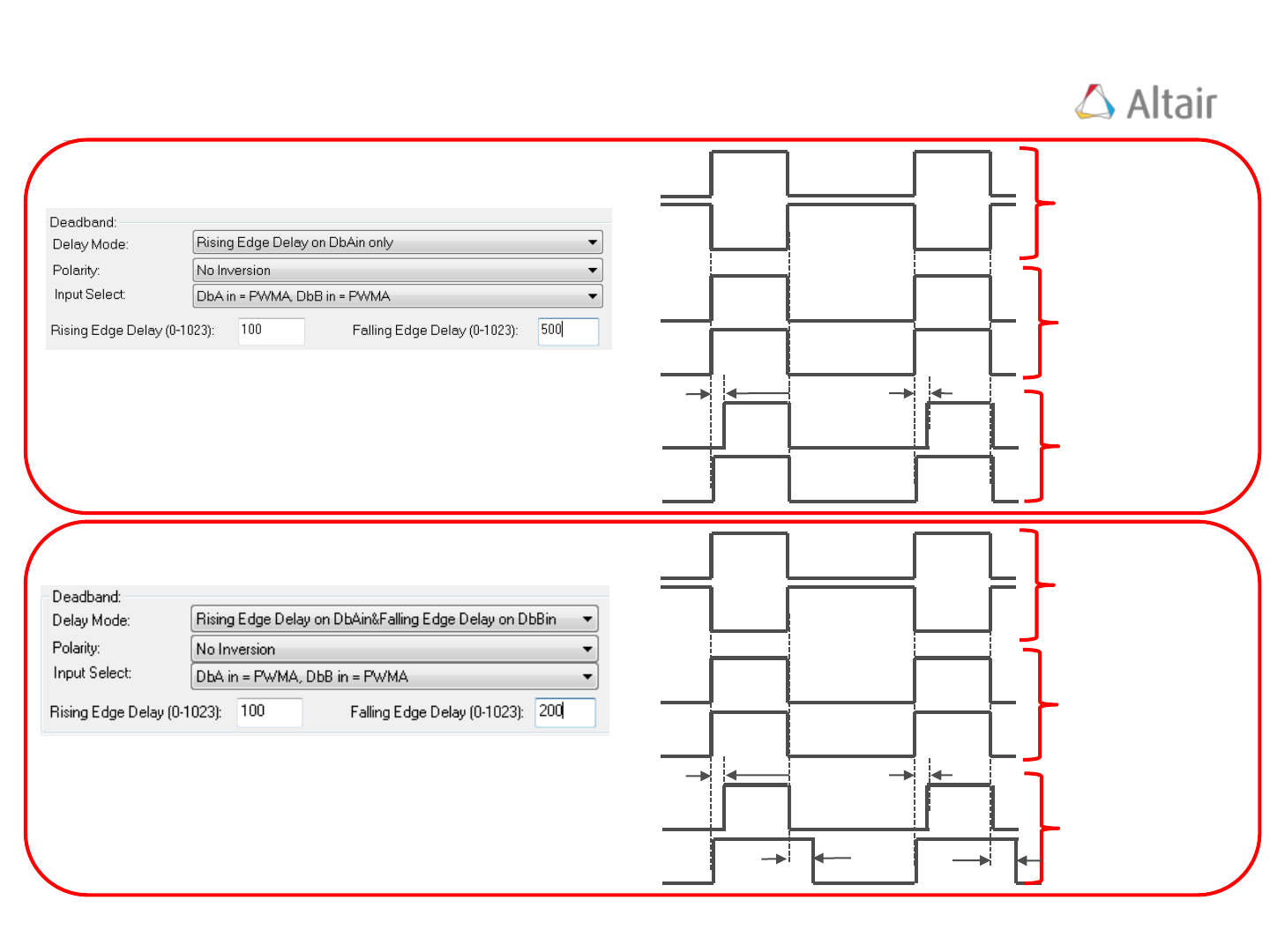

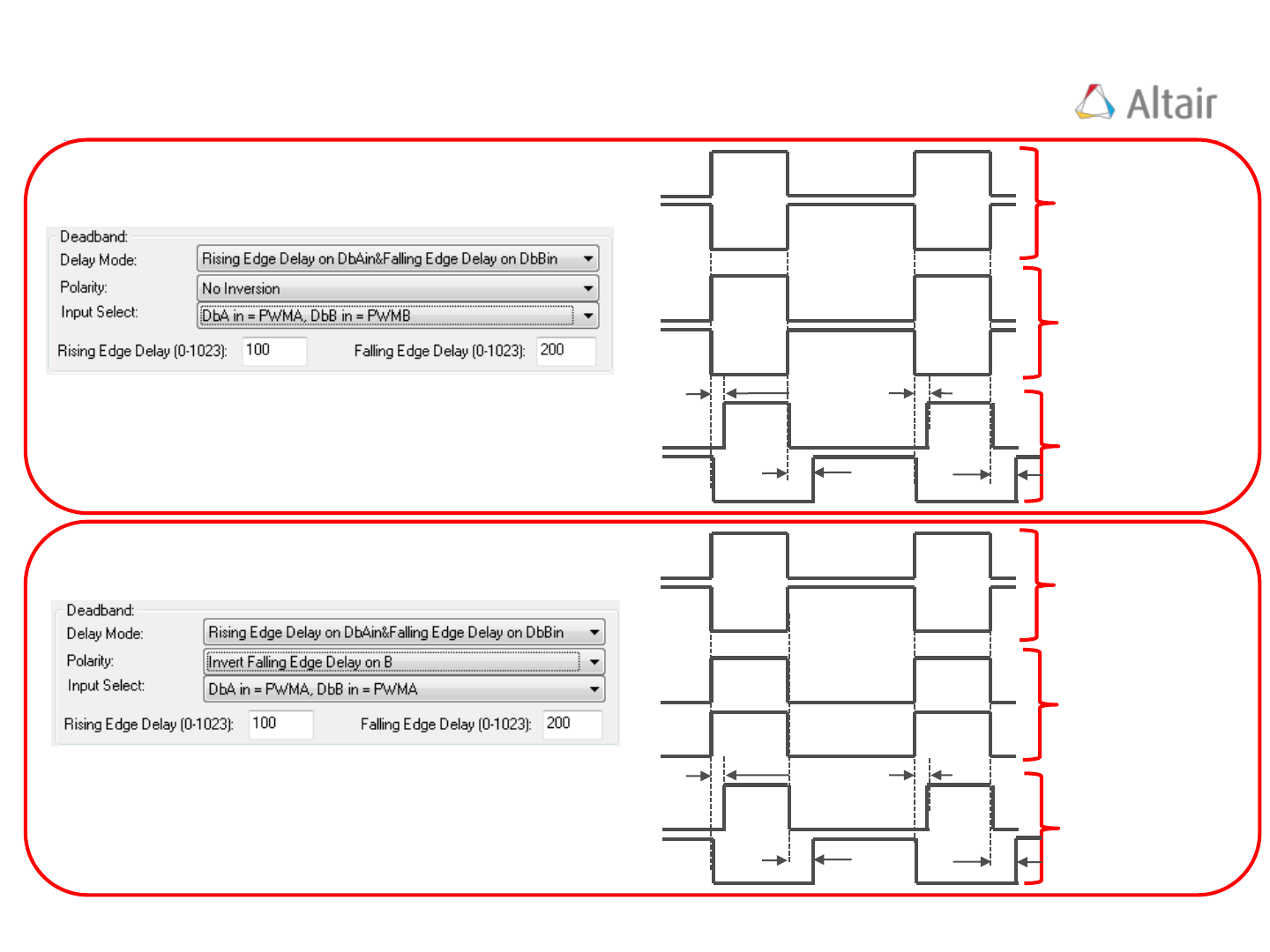

VisSim ePWM – Deadband Module Examples

26

PWMA

PWMB

PWM input signals

from Action Qualifier

Module

PWM signals after

Input Select

PWM output signals

from Deadband

Module

Example 1:

100 counts

DbA

DbB

PWMB

PWMA

PWMA

PWMB

PWM input signals

from Action Qualifier

Module

PWM signals after

Input Select

PWM output signals

from Deadband

Module

Example 2:

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

200 counts

100 counts

DbA

DbB

PWMB

PWMA

VisSim ePWM – Deadband Module Examples

27

PWMA

PWMB

PWM input signals

from Action Qualifier

Module

PWM signals after

Input Select

PWM output signals

from Deadband

Module

Example 3:

100 counts

DbA

DbB

PWMB

PWMA

PWMA

PWMB

PWM input signals

from Action Qualifier

Module

PWM signals after

Input Select

PWM output signals

from Deadband

Module

Example 4:

200 counts

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

VisSim ePWM – Event Time Module

28

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

VisSim ePWM – Fault Handling

29

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

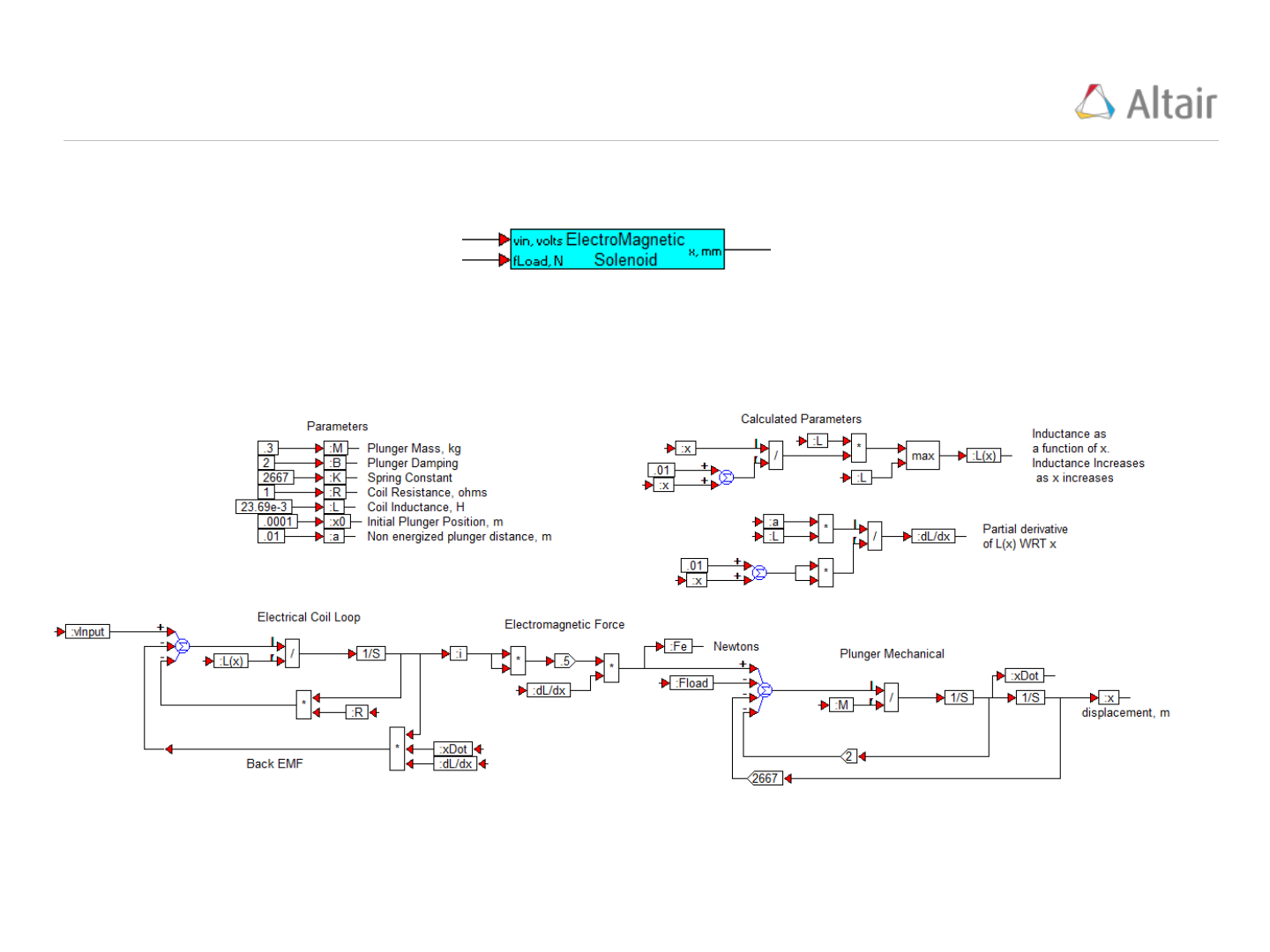

PWM Example – Solenoid Control

30

Solenoid Model (Top Level):

Solenoid Model (Details):

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

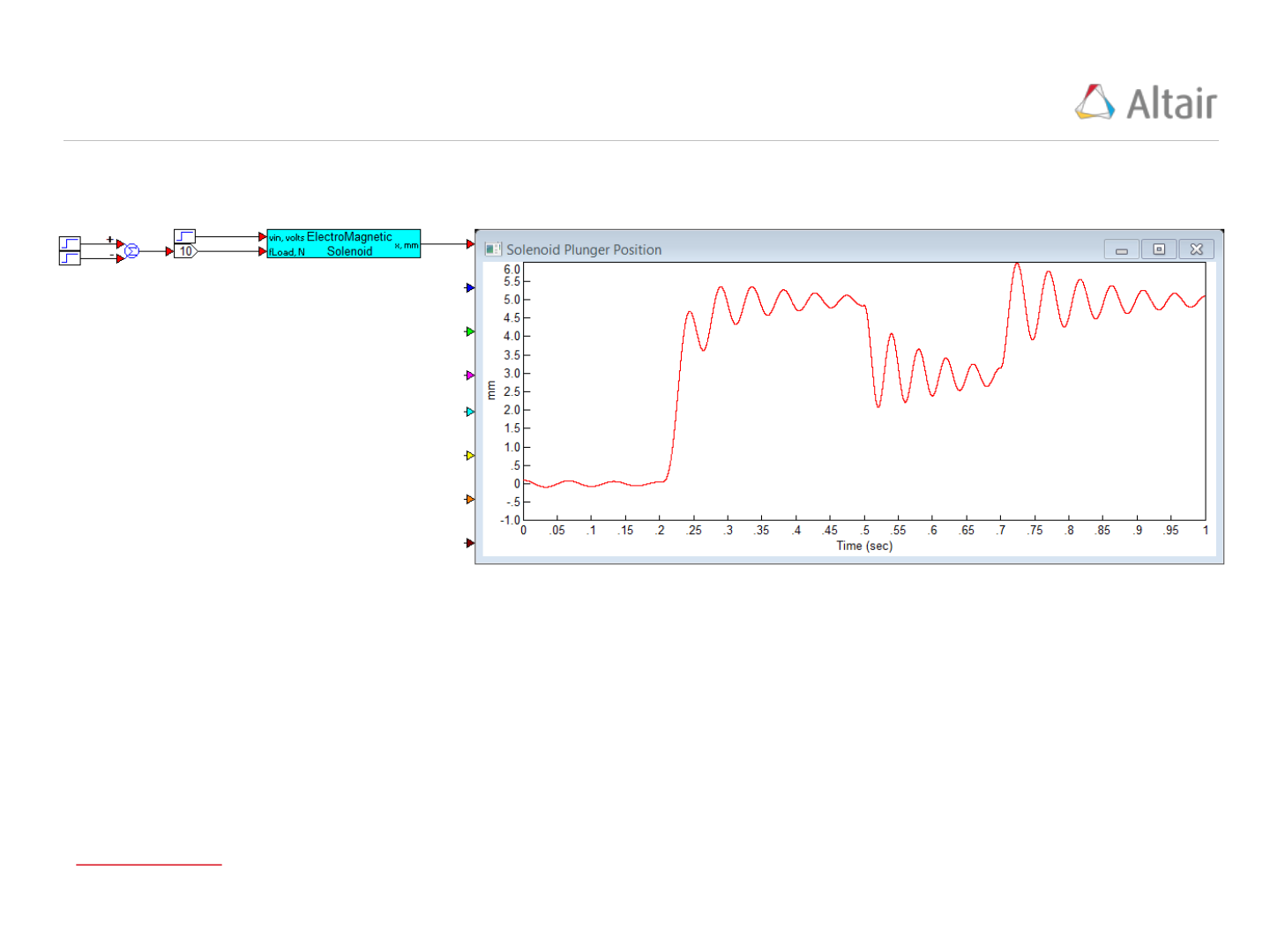

PWM Example – Solenoid Simulated Response

31

Solenoid Model Simulation Response:

Vin = 5 volts applied at 0.2 seconds

fLoad = 10 Newtons applied at 0.5 seconds and removed at 0.7 seconds

Simulation Update Time = 1e-5 seconds

Solenoid Model

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

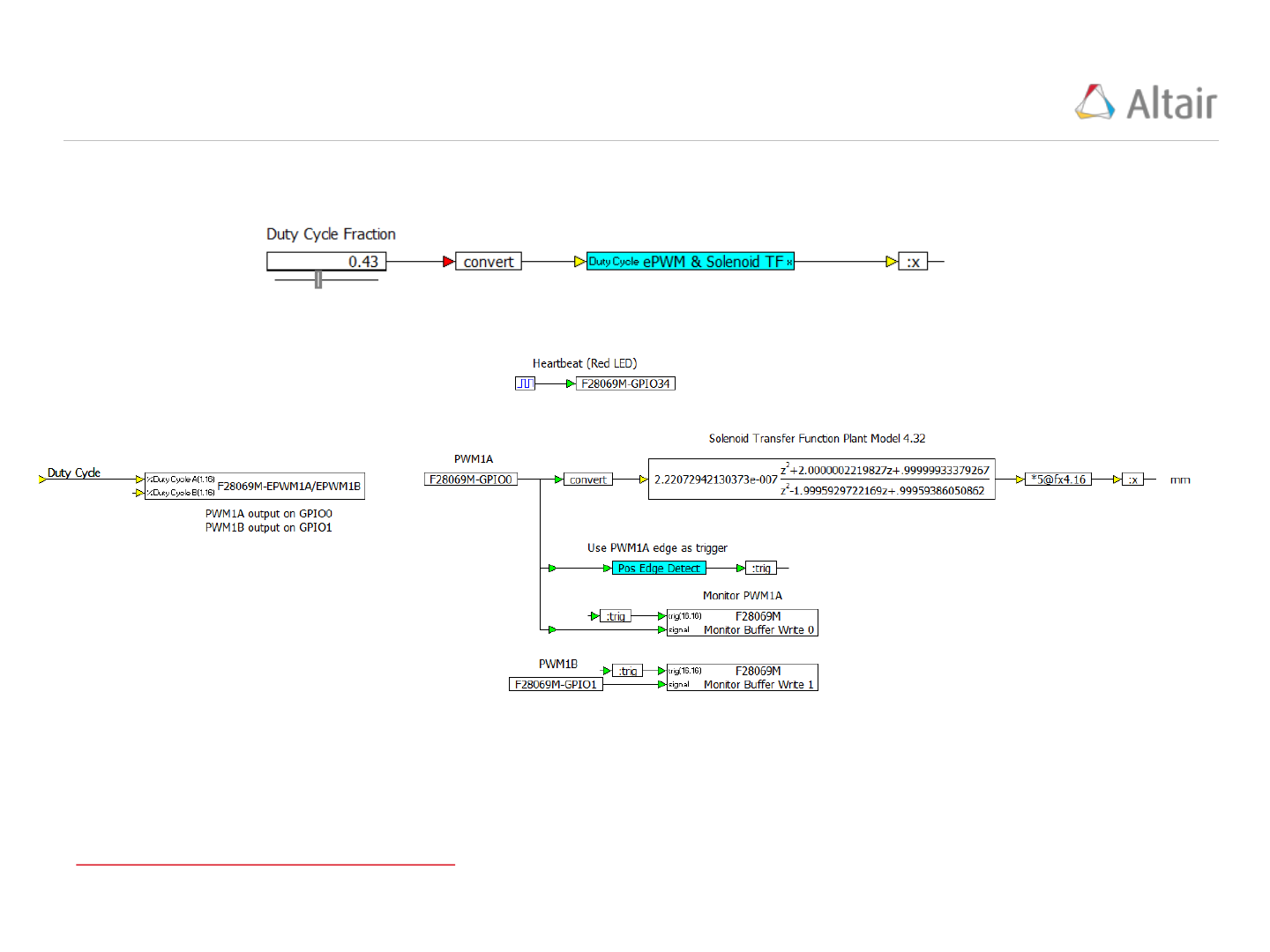

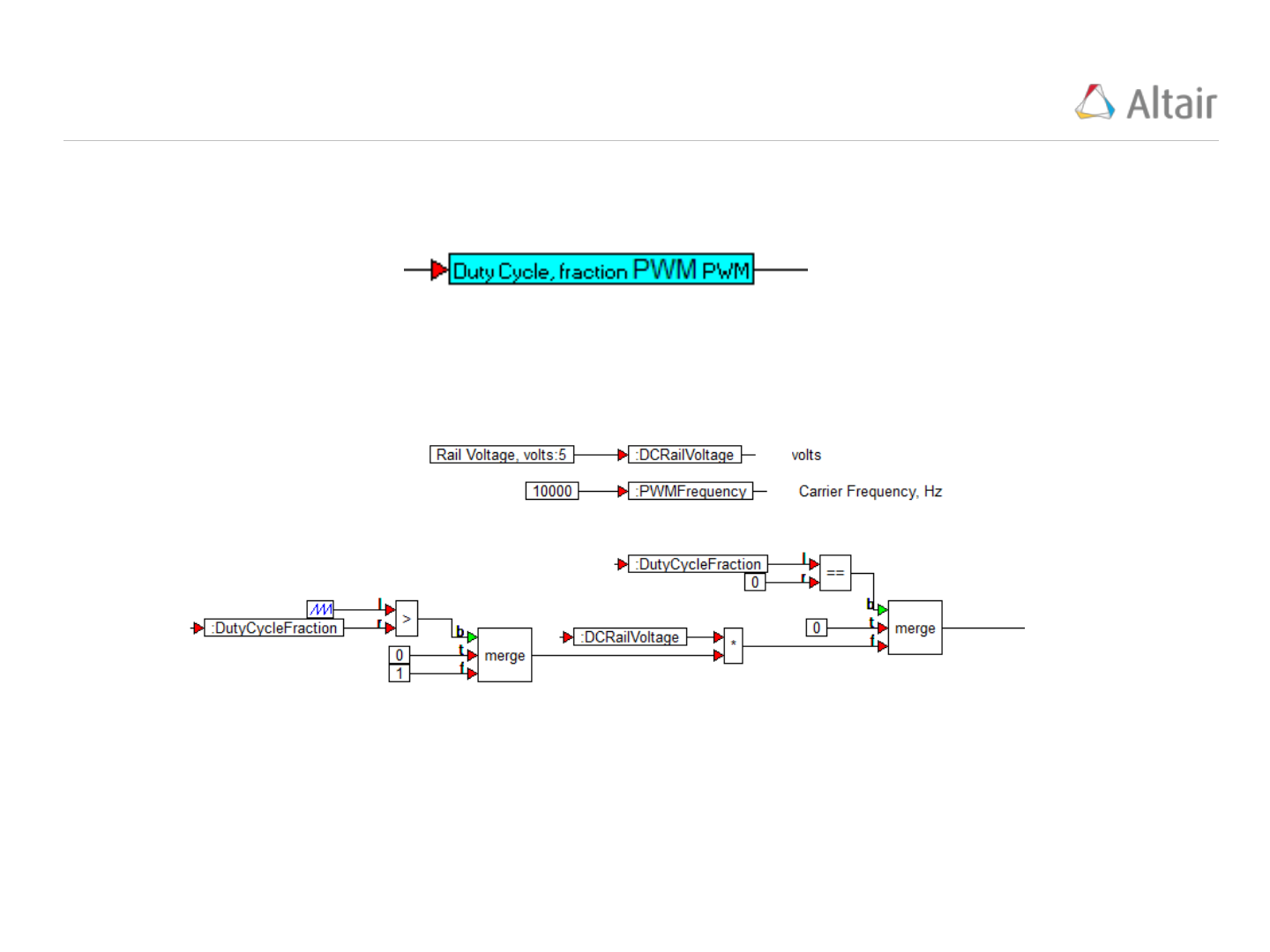

PWM Example – Solenoid PWM Generator

32

PWM Model (Top Level):

PWM Model (Details):

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

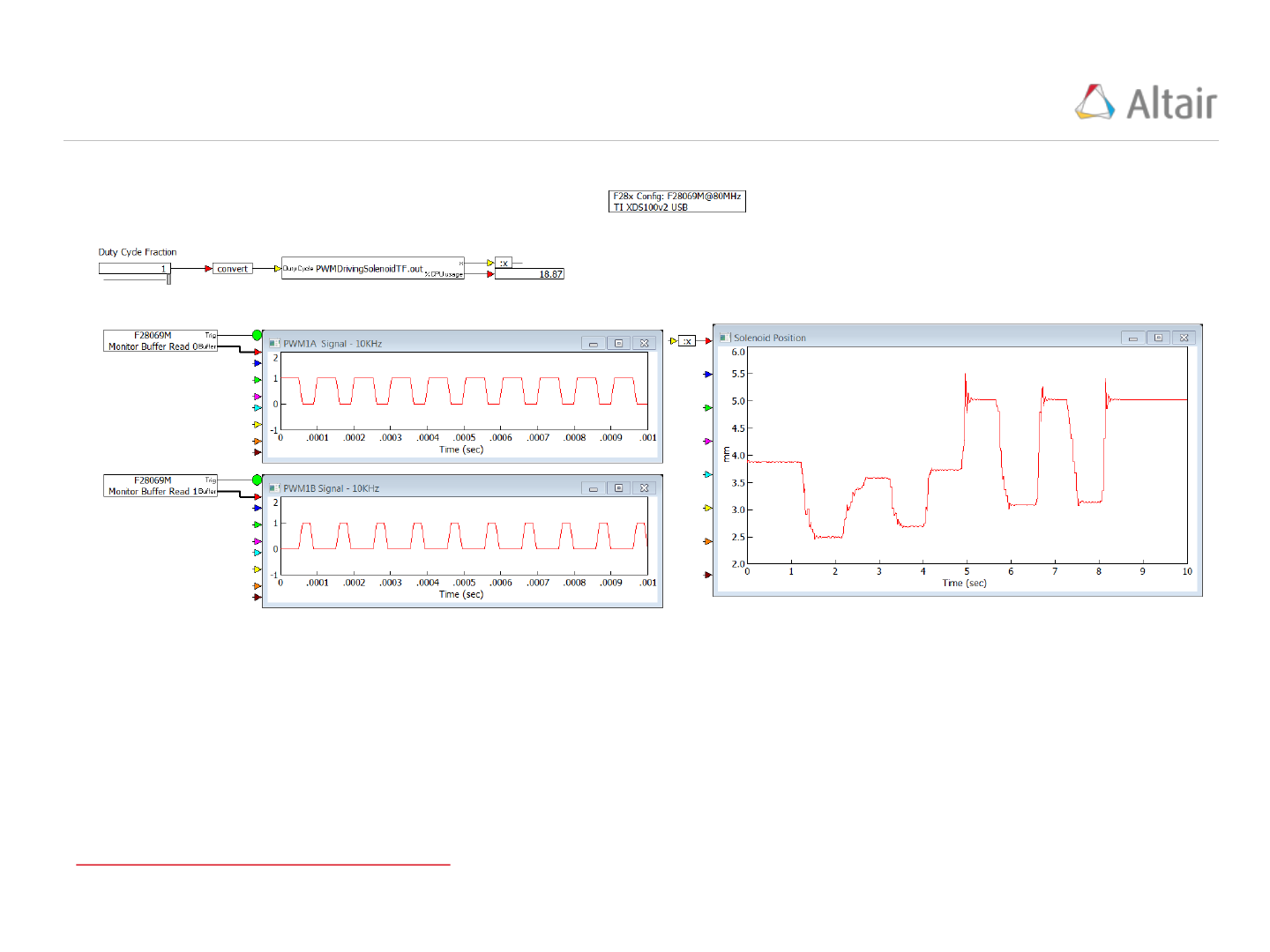

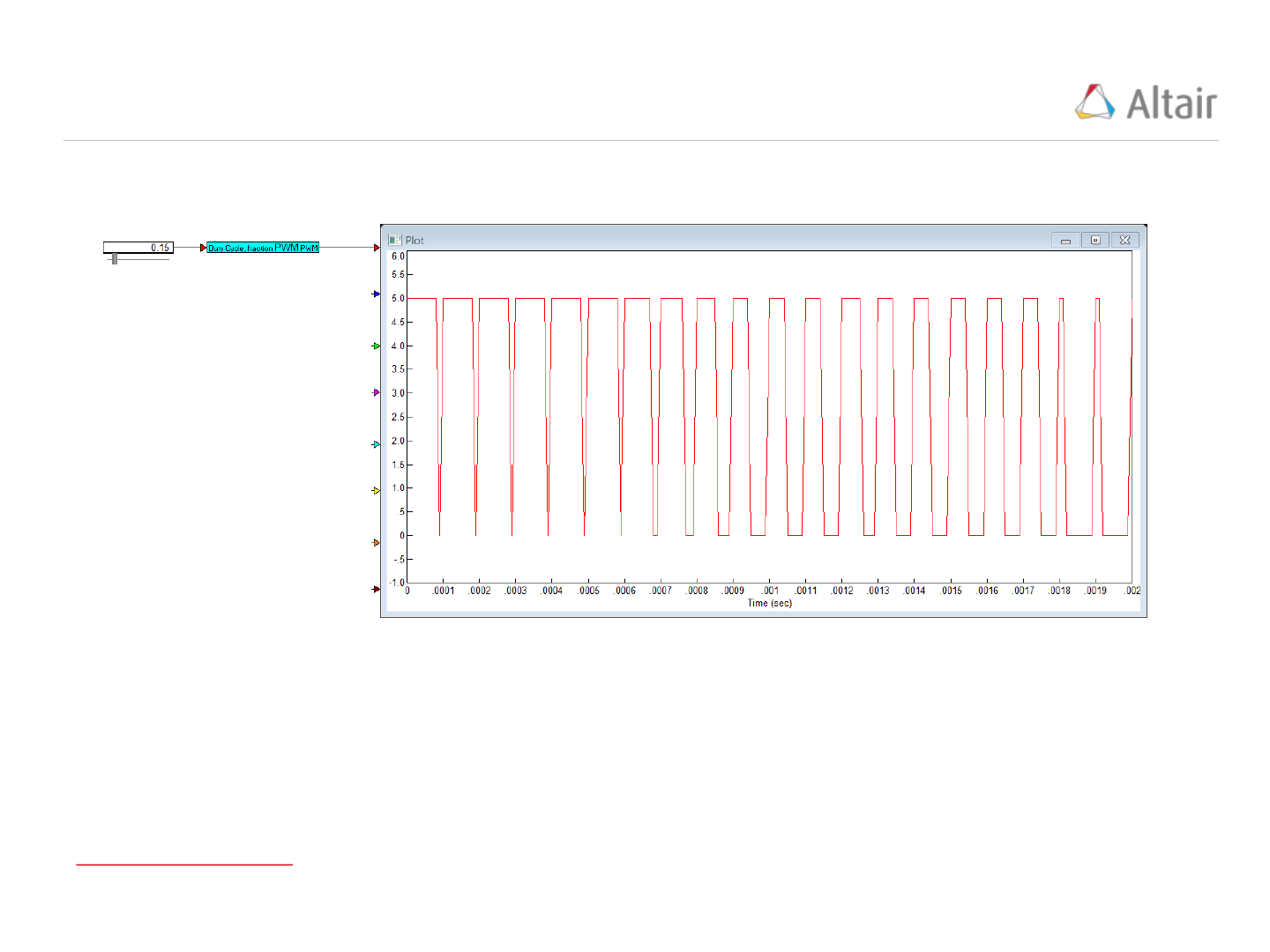

PWM Example – Solenoid PWM Generator Simulation

33

PWM Model Simulation Results:

PWM Carrier Frequency = 10kHz

Duty Cycle Slider swept from .8 to .15 during the .002 second simulation

Simulation Update Time = 1e-5 seconds

PWM Generator Model

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

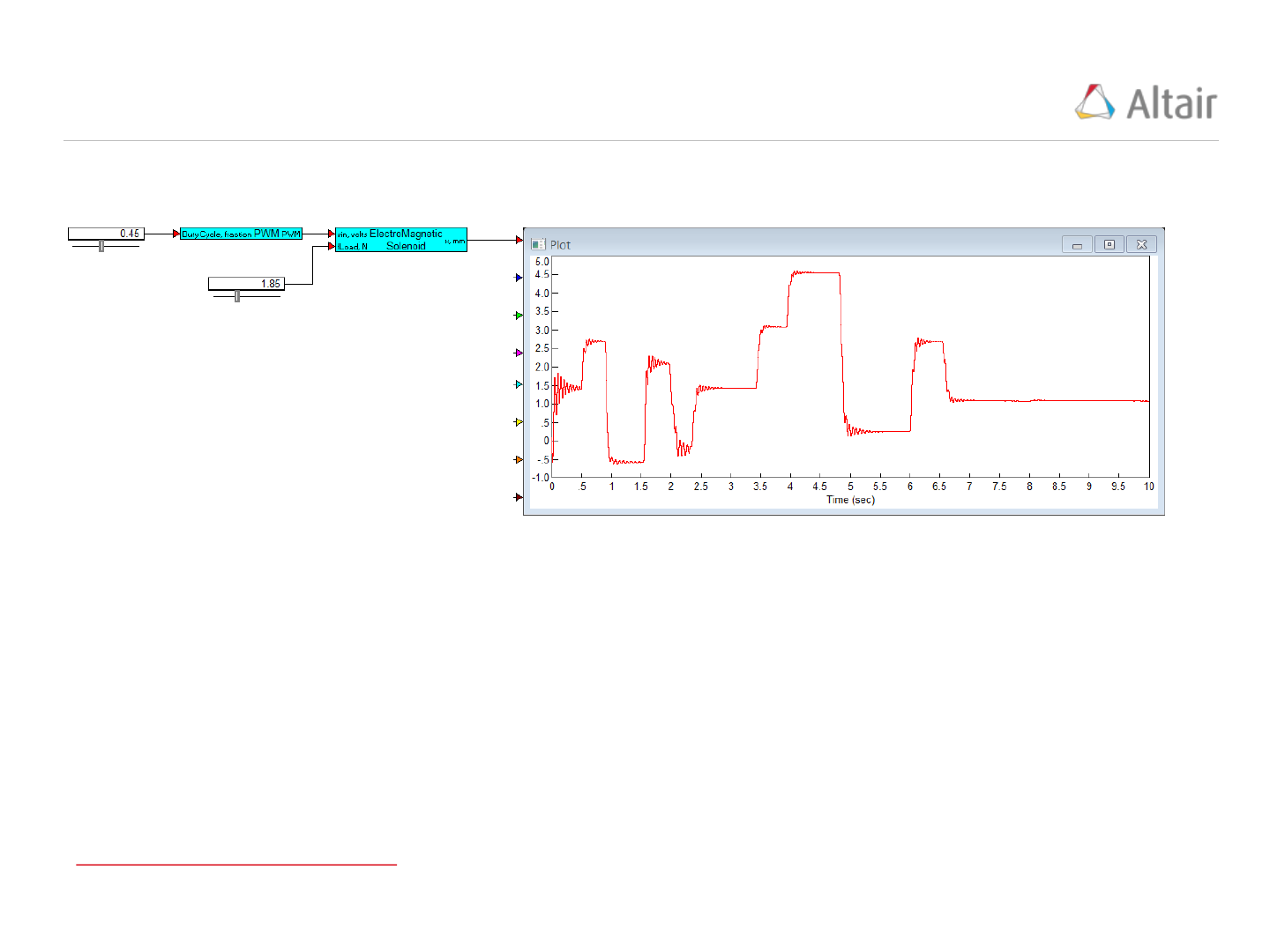

PWM Example – Solenoid w/PWM Control Simulation

34

Solenoid w/PWM Control Simulation Results:

PWM Carrier Frequency = 10kHz

Duty Cycle Slider swept randomly between 0 and 1 during the 10 second simulation

Simulation Update Time = 1e-5 seconds

Solenoid Model with PWM Control

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

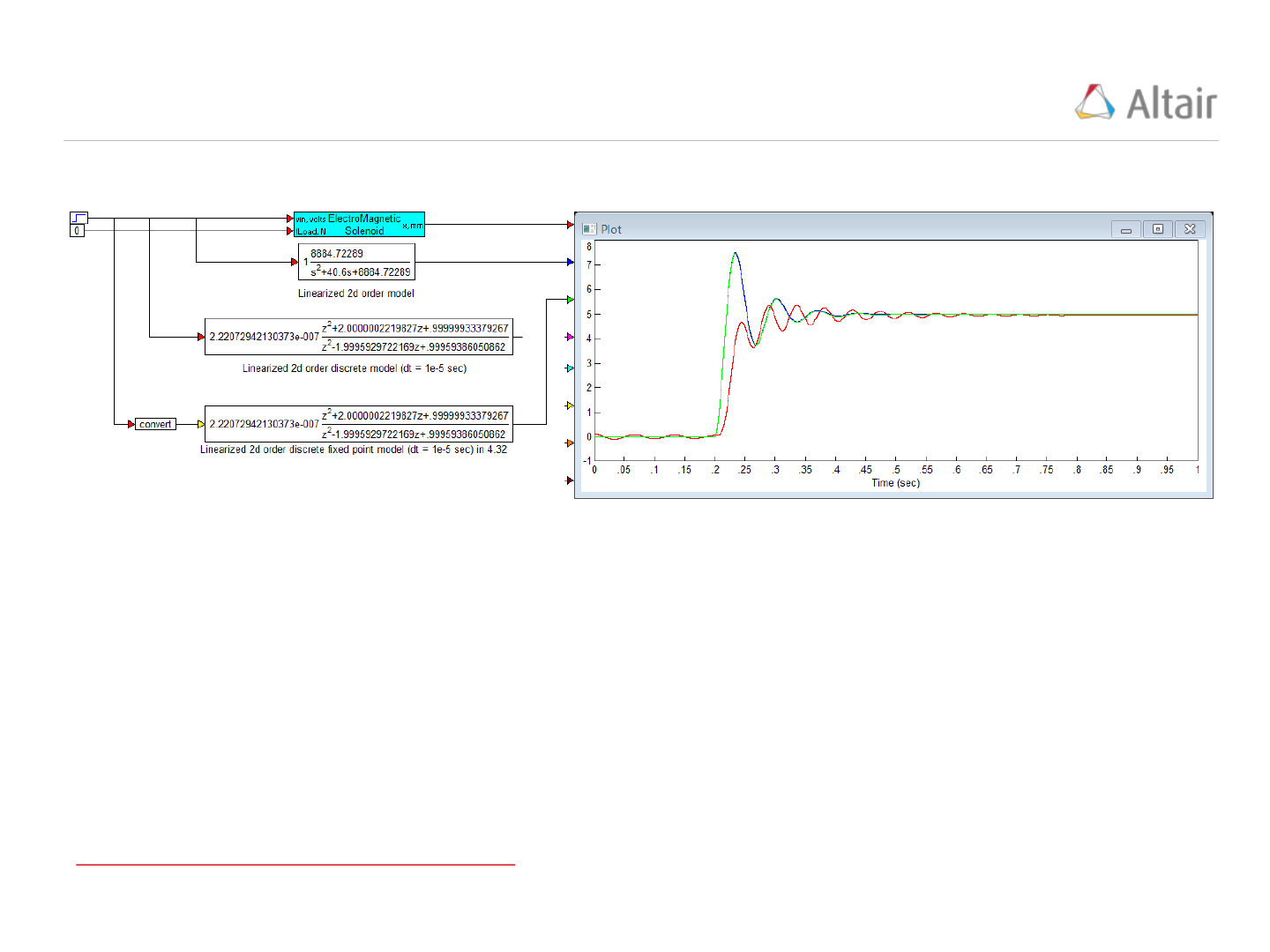

PWM Example – Solenoid Approximate Transfer Function

35

Solenoid Approximate Fixed Point Transfer Function

Vin = 5 volts

Fload = 0 Newtons

Simulation Update Time = 1e-5 seconds

Solenoid Approximate Transfer Function Model

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

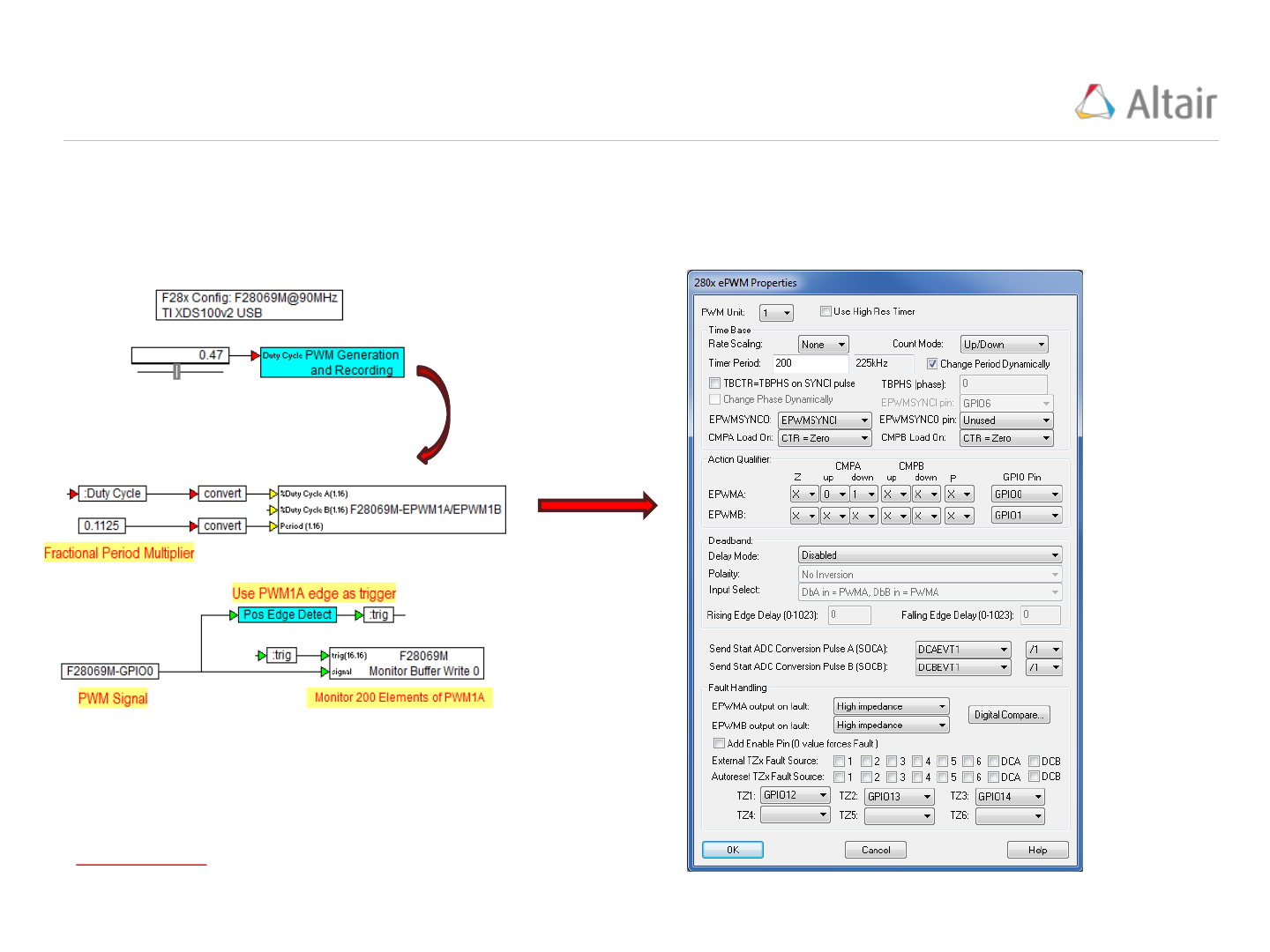

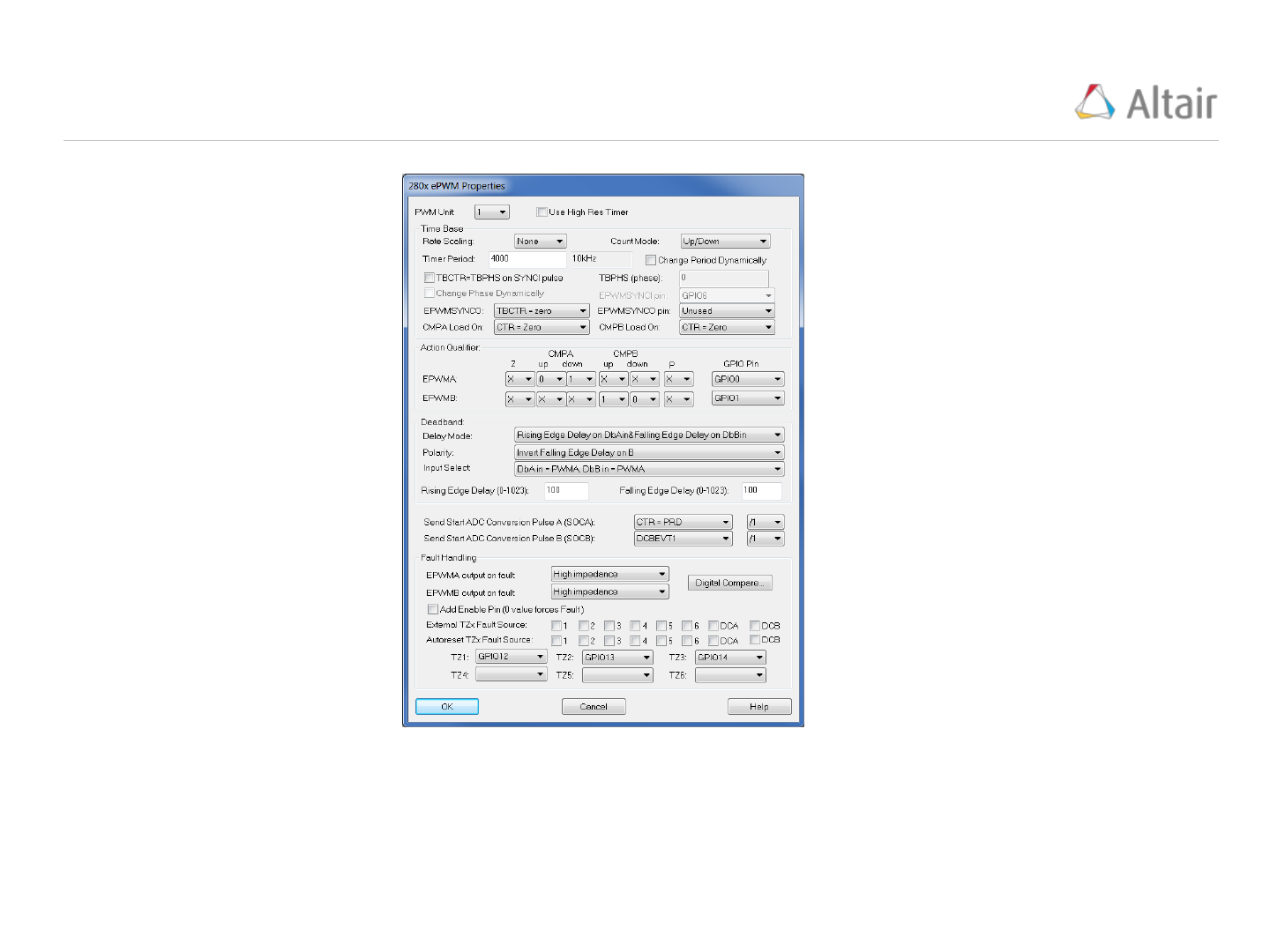

PWM Example – Solenoid PIL PWM Configuration

37

PWM Configuration

Carrier Frequency = 10kHz

GPIO0 = PWM 1A output

GPIO1 = PWM 1B output

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

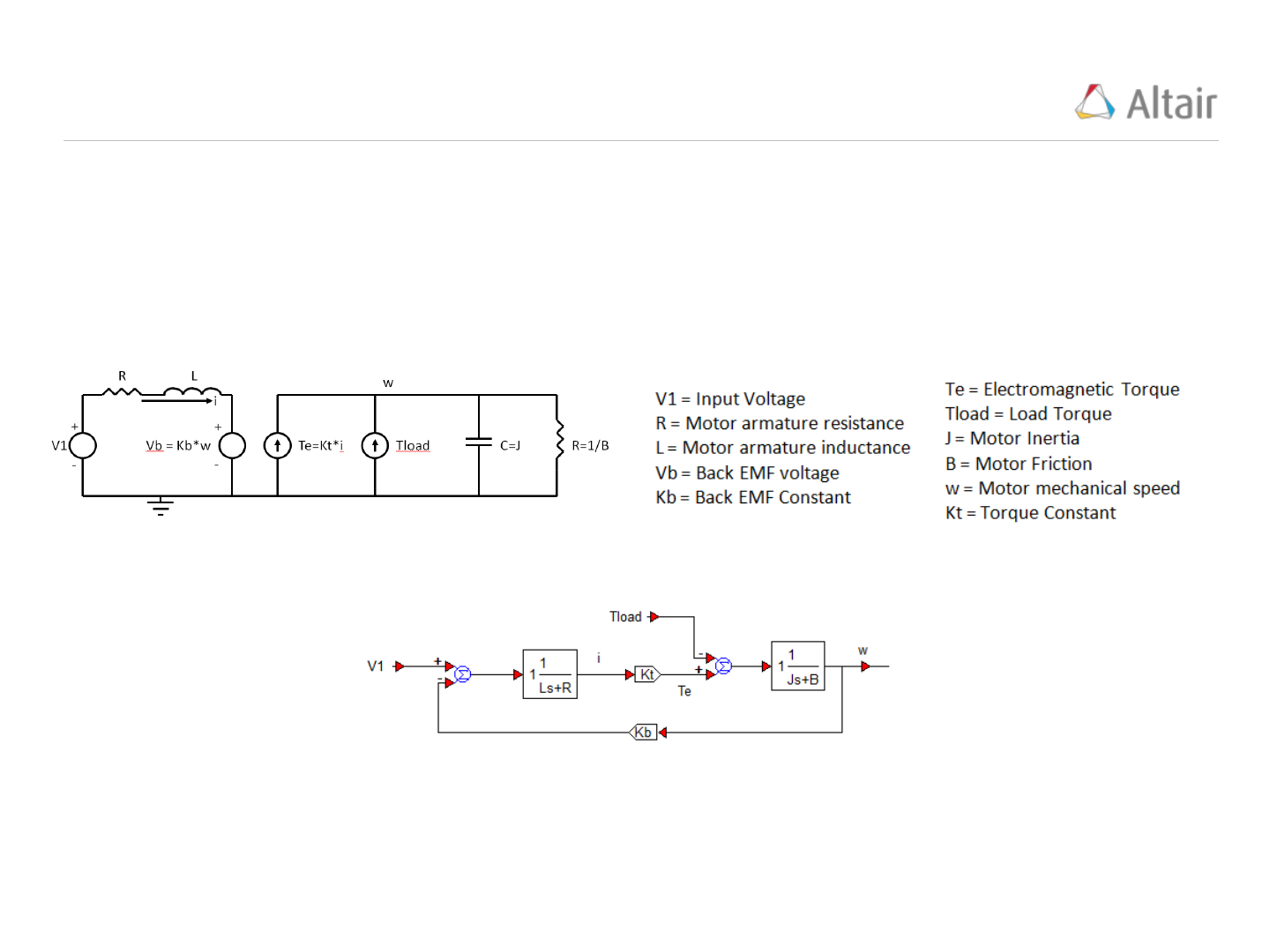

PWM Example – Motor Control

40

It is important to understand how the PWM Carrier Period (and Frequency) is selected.

To do this we will create a basic motor model, identify its fundamental time constant, and then select

the PWM Carrier Period short enough to produce an acceptable level of motor velocity fluctuation.

Basic Motor Model:

Where:

The equivalent motor block diagram becomes:

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

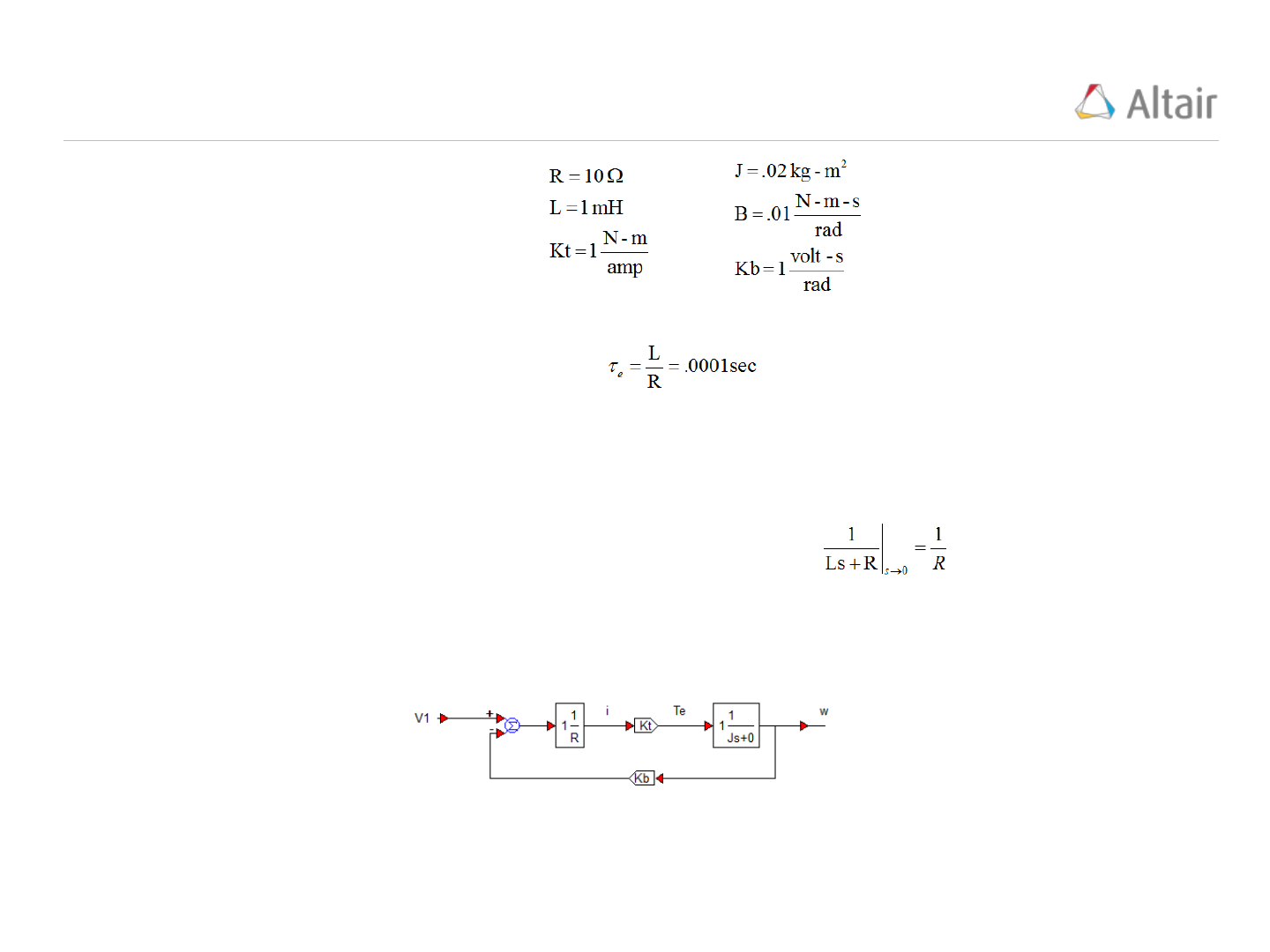

Motor Dynamics – Electrical Time Constant

41

Using the following example values;

The Electrical Time Constant is calculated as:

To calculate the Mechanical Time Constant, the following simplifications are applied;

Tload = 0 (no load torque)

Motor friction, B = 0

And the electrical dynamics are replaced by their dc-value;

Applying these assumptions, the motor model block diagram simplifies to:

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

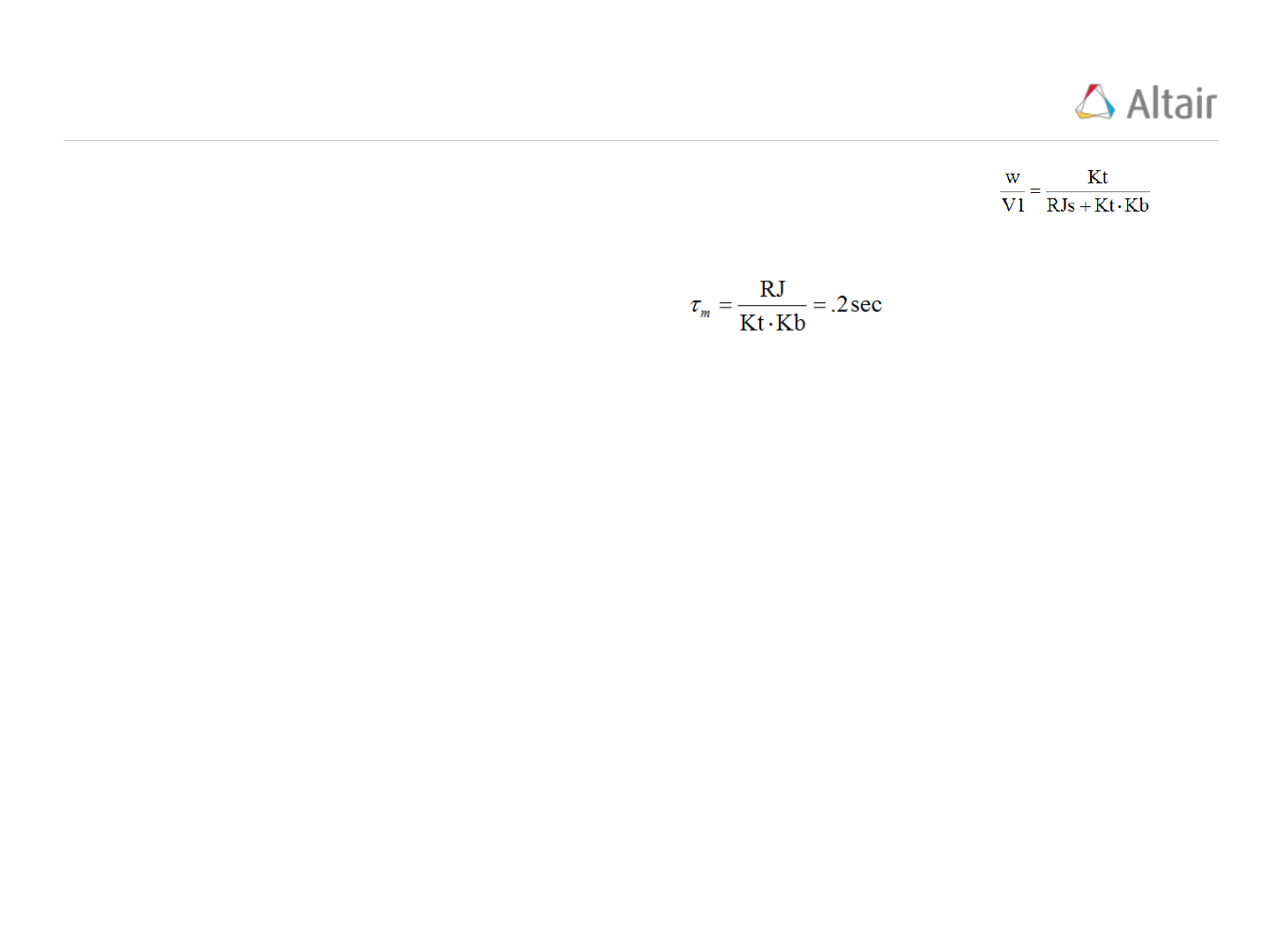

Motor Dynamics – Mechanical Time Constant

42

The closed loop transfer function of the simplified motor model is calculated as:

And the Mechanical Time Constant is calculated as:

In successful applications, the Mechanical Time Constant should be the fundamental (or dominant)

time constant, typically 100 to 1000 times slower than the electrical time constant.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

PWM Carrier Period & Frequency

43

The PWM Carrier Period, Tpwm, and Frequency, Fpwm, is calculated to produce an acceptable value

of motor velocity fluctuation.

As an example, assume that a 0.05% velocity fluctuation is the goal.

If the initial motor velocity, w(0) = 1, and the dominant time constant of the motor = mechanical time

constant is 0.2 seconds,

Then the problem is that of solving the mechanical time

constant for the Tpwm (PWM Carrier Period):

Fpwm = 1/Tpwm = 10KHz.

The typical range for the PWM Carrier Frequency is 10KHz <= Fpwm <= 40KHz. Using frequencies

less than 10KHz result in unacceptable motor velocity ripple and values greater than 40KHz tend to

increase the transistor switching frequency (in the H Bridge) to a level that causes them to heat up

and prematurely fail.

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

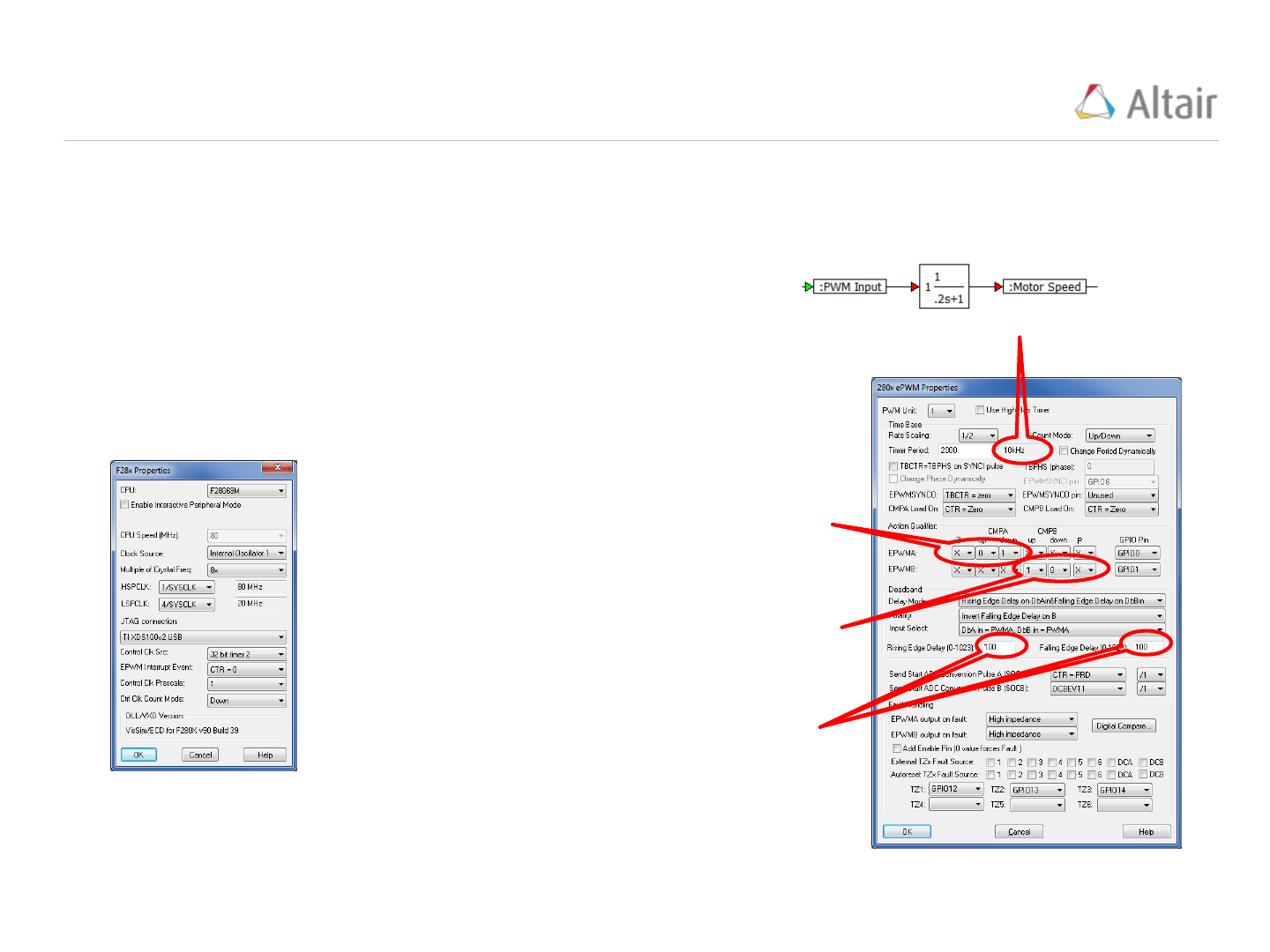

Motor Speed Response to PWM

44

This example illustrates the response of a motor transfer function model to a PWM signal implemented

on the F28069M LaunchPad target. Values from the previous “Motor Dynamics” example are used.

The motor model is defined as a unity gain first order transfer

function with a mechanical dominant time constant = .2 seconds

(right)

The PWM Carrier Frequency is set to 10KHz. Using the following settings:

F28x Properties: CPU Speed

(MHz) = 80MHz

ePWM Properties:

Rate Scaling = 1/2

Count Mode = up/down

Timer Period = 2000

Since the PWM Carrier Frequency is 10KHz, the target model update frequency is selected to be

20 times faster (200KHz), this is equivalent to a target update time = 1/200KHz = 5e-6 sec.

PWM Carrier Frequency

if counting “up” and TBCTRB goes thru

CMPB, set EPWMB = 1

if counting “down” and TBCTRB goes

thru CBMPB, set EPWMB = 0

if counting “up” and TBCTRA goes thru

CMPA, set EPWMA = 0

if counting “down” and TBCTRA goes

thru CMPA, set EPWMA = 1

Rising and Falling edge deadbands (time

delays) normally set to the same value

(units are ticks)

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

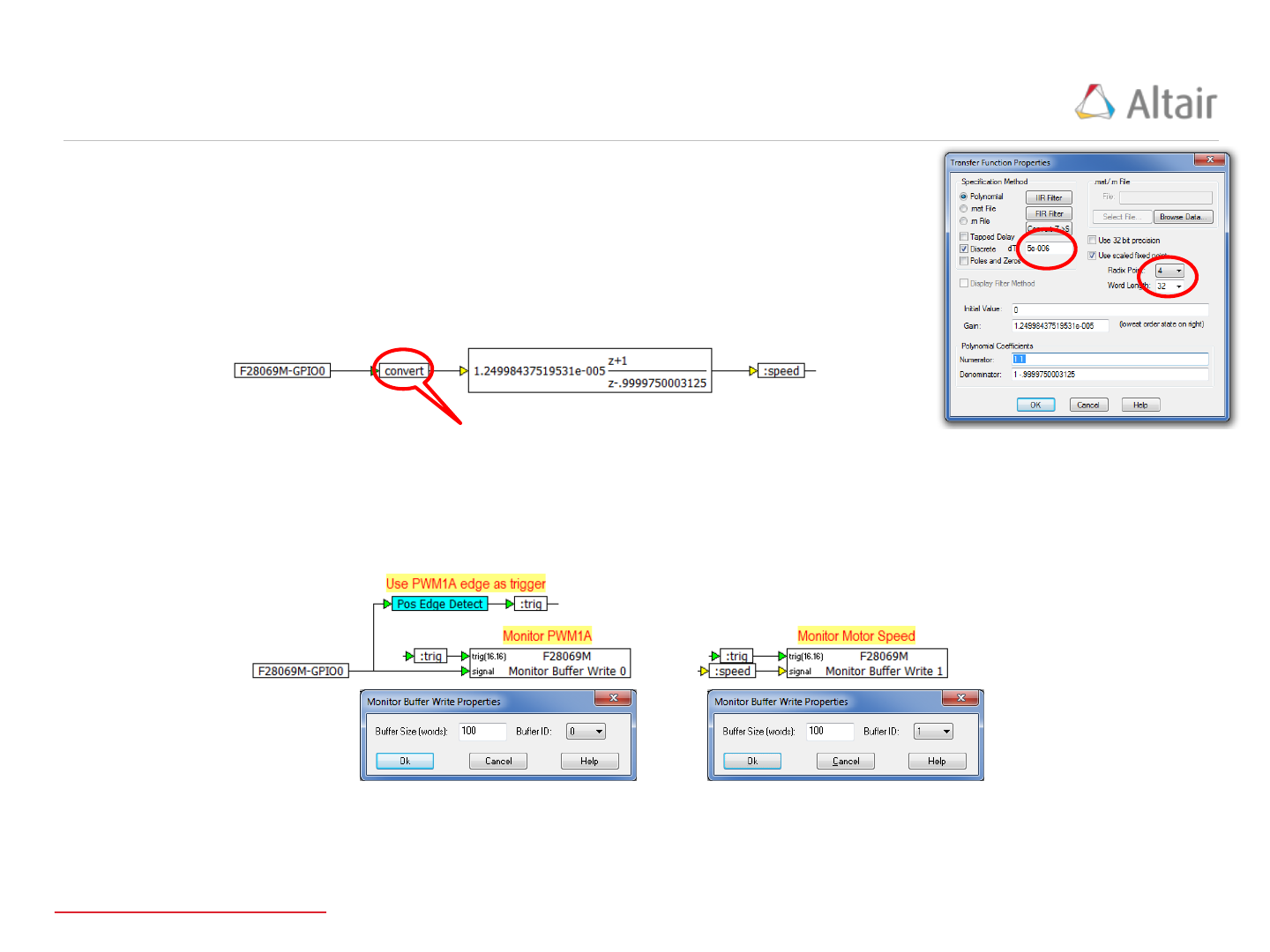

Motor Speed Response – Motor Model

45

The motor model transfer function is converted to a fixed point discrete

transfer function, format 4.32, using an update time = 5e-6 sec (right)

Format 4.32, same as the transfer function

The motor model transfer function receives the PWMA signal from

GPIO0 (below) NOTE: PWMB is not used in this example.

Monitor Buffers are used to record 100 elements of PWM data (into Monitor Buffer 0) and Motor

speed (into Monitor Buffer 1) – (below):

The trigger signal “:trig” is pulsed every time a PWM cycle begins (10KHz)

View source model in VisSim

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

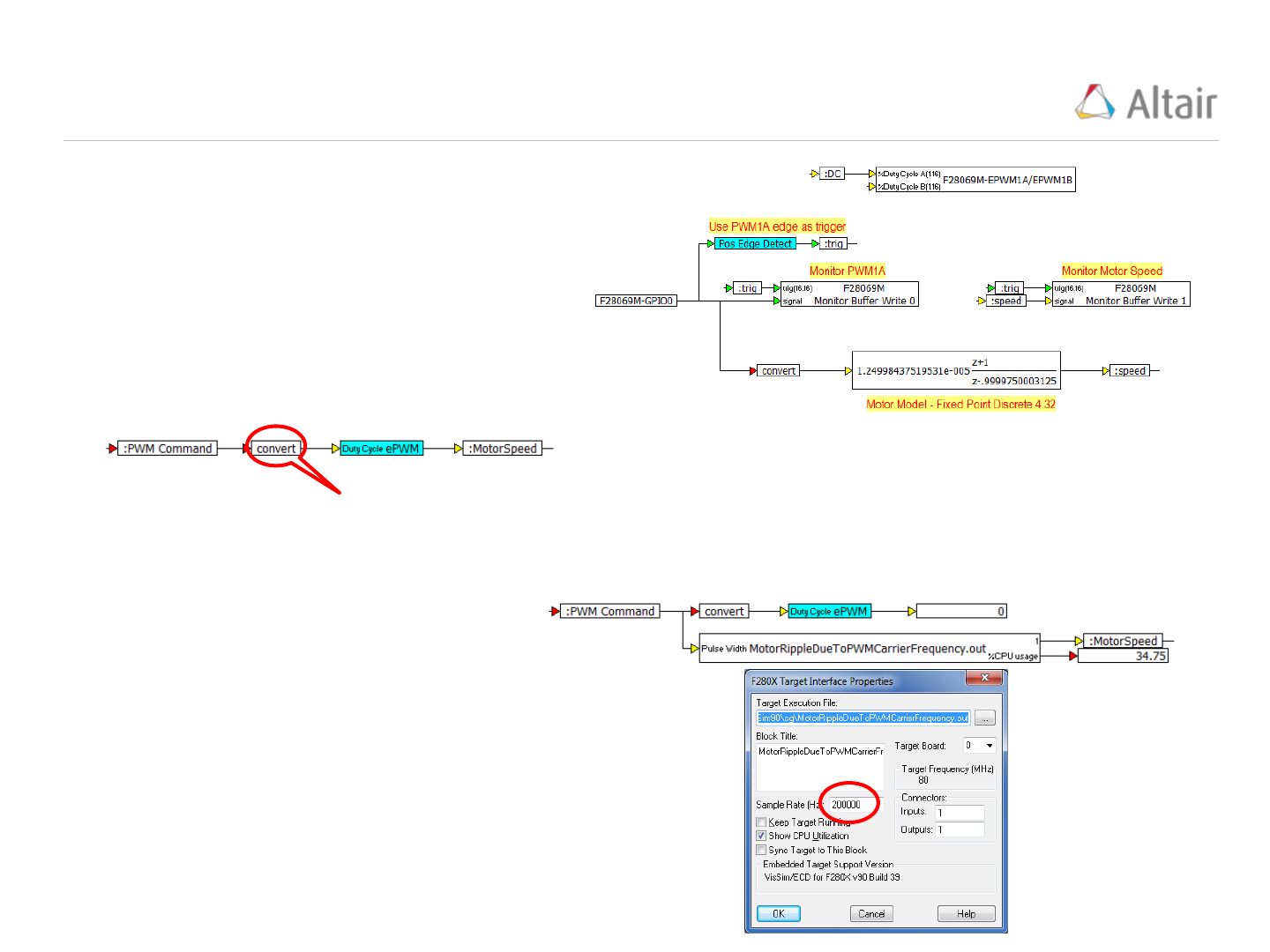

Motor Speed Response – Source Model

46

The completed Source model becomes

(right):

Format 1.16 required as the duty cycle command value for the ePWM block

C Code is generated for “ePWM” and compiled into “MotorRippleDueToPWMCarrierFrequency.out”

by applying the “Code Gen…” option under the “Tools” menu.

The source model is captured in a

compound block named “ePWM” (below):

The Debug model is created from the

Source model by replacing the “ePWM”

compound block with a “TargetInterface”

block configured to read the “.out” file

produced by the Source model. The

“TargetInterface” is configured to execute

at a “Sample Rate (Hz):” = 200KHz rate

(right):

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

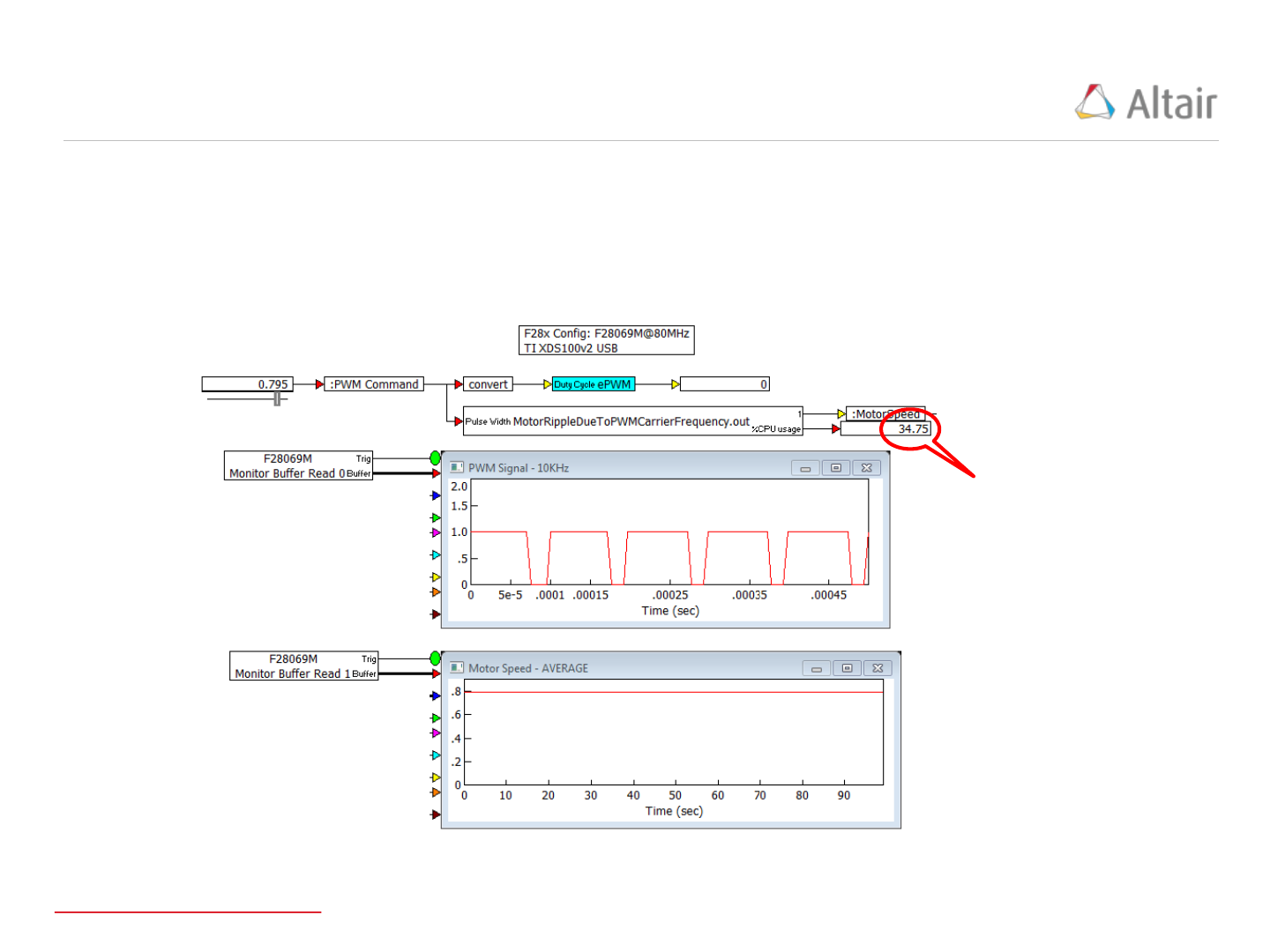

Motor Speed Response – Debug Model

47

The VisSim Debug model, which includes the “TargetInterface” block, is configured to execute at a 0.01

second update time allowing the JTAG interface adequate time to transfer the Monitor Buffer contents.

The competed Debug model and results showing the PWM signal and the motor speed buffers are

presented below:

Fixed Point motor model

transfer function % CPU

utilization.

NOTE: this model would not

execute at the 200KHz rate if

Fixed Point were NOT used.

NOTE: Debug model settings: dt = 0.01 seconds, "End(sec)" = 25;

"Run in Real Time" checked, "Auto Restart" checked, and "Retain

State" checked.

View debug model in VisSim

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

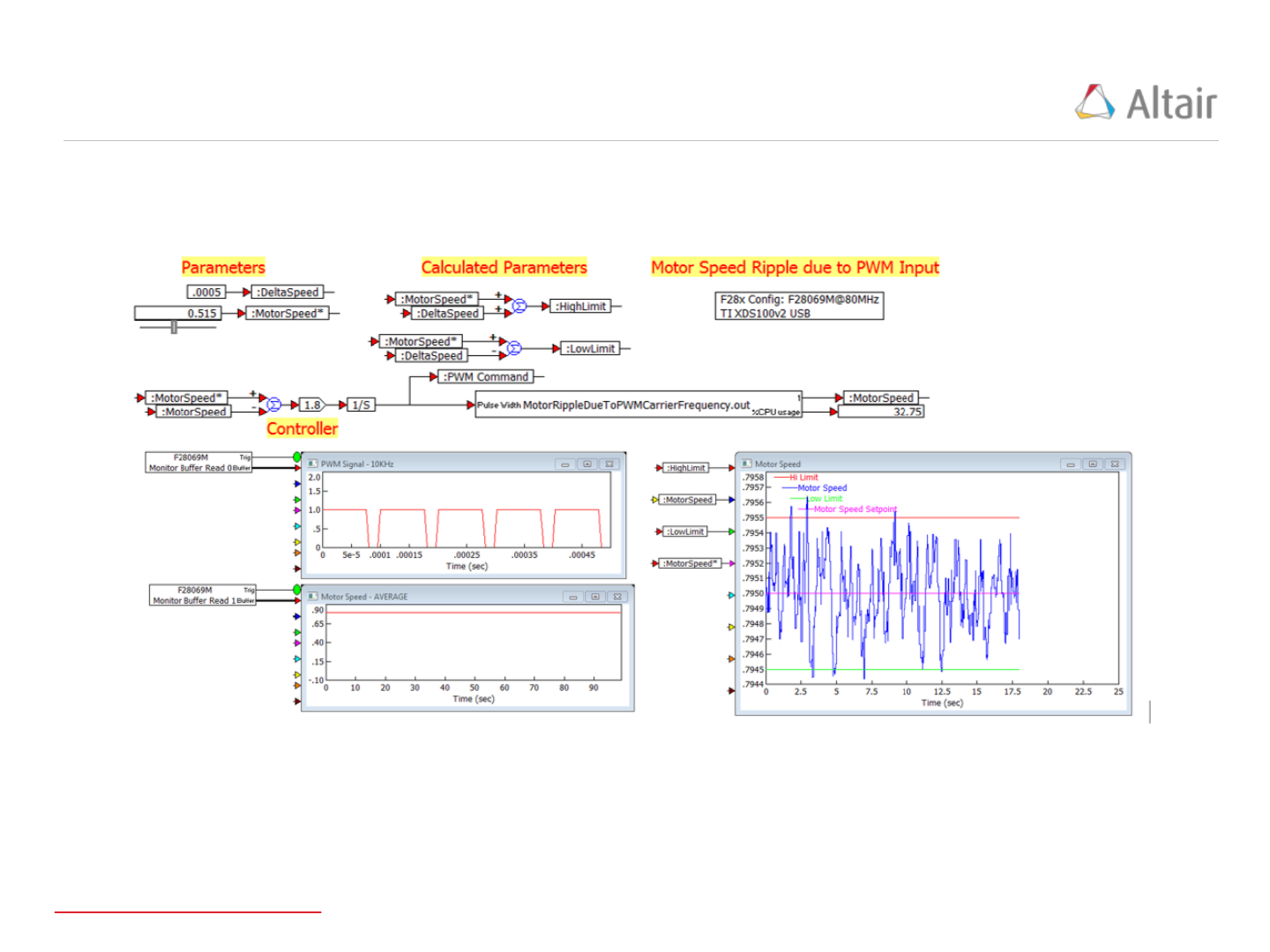

Motor Speed Response – Speed Jitter Results

48

The Debug model was allowed to restart several times with the “MotorSpeed*” fixed at .795 to

determine if the Motor Speed Jitter was within the +/- 0.0005 unit limits (below, right)

Motor Speed response to PWM is within

the +/- 0.0005 unit limits

View debug model in VisSim

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

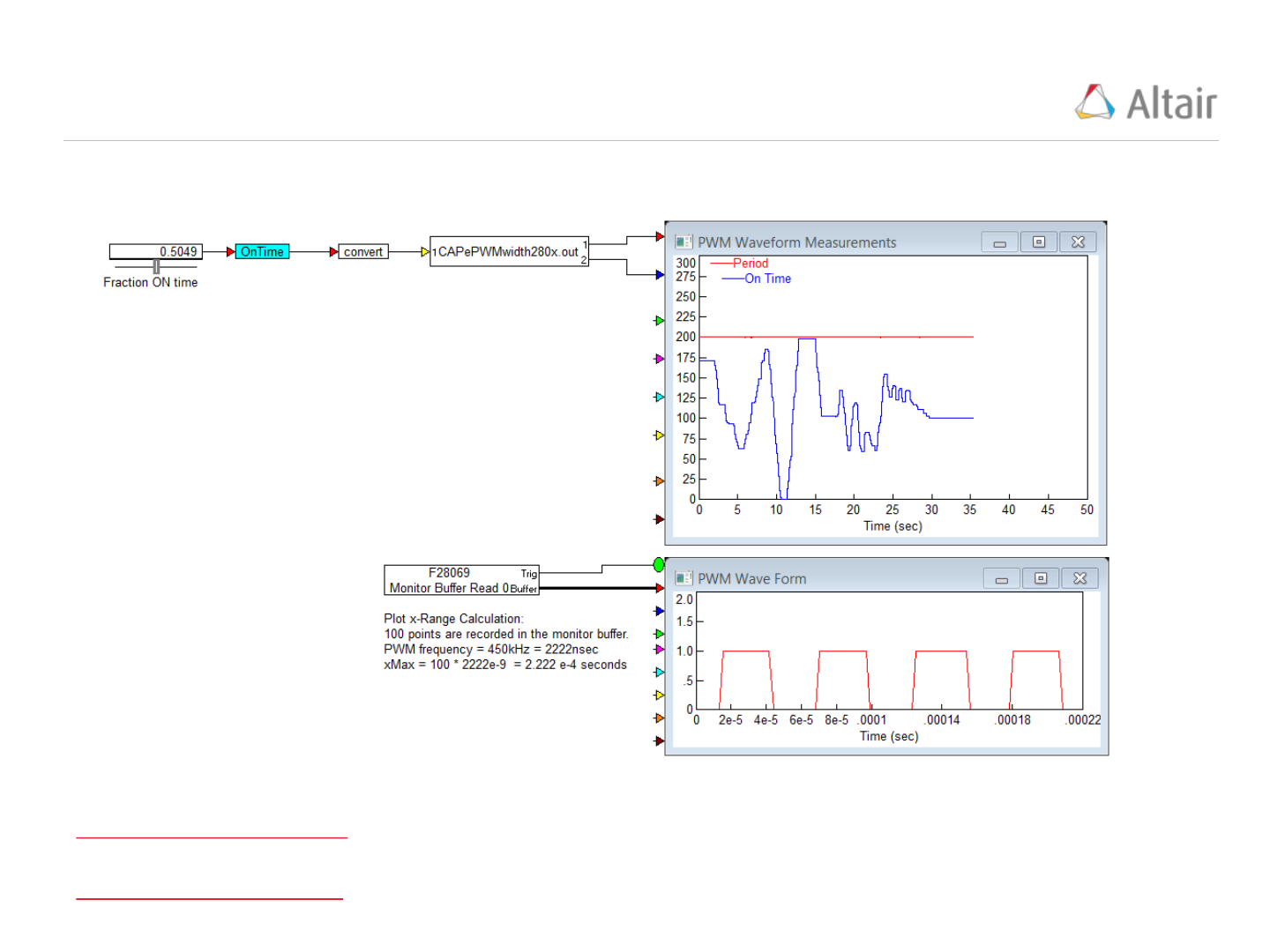

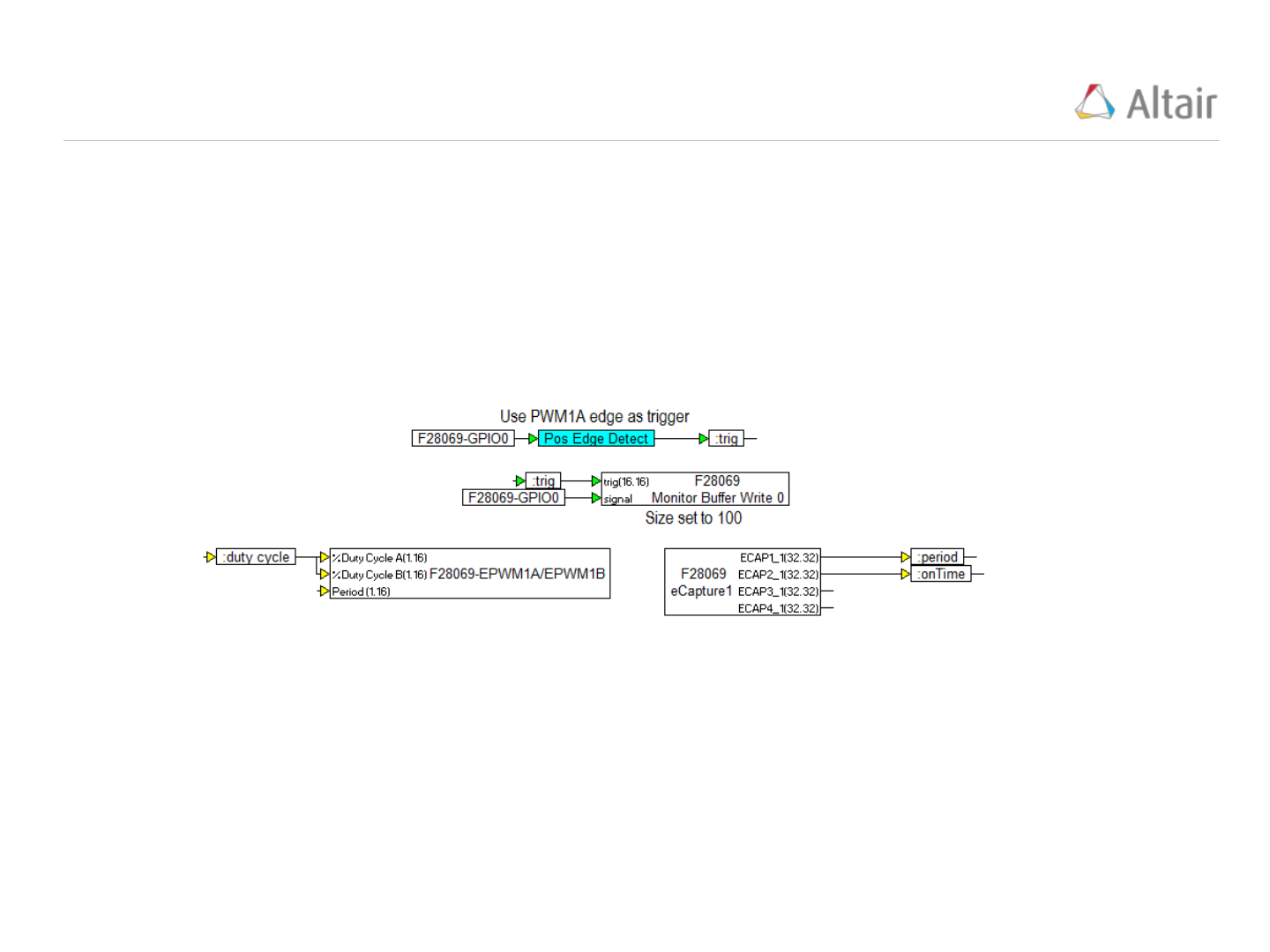

Record ePWM timing using eCap Block (1/5)

49

The “eCap” block (Embedded/Piccolo/eCap) provides the ability to record the “on” and “off” times of

PWM signals. Let’s create a VisSim model that outputs a PWM signal on GPIO0 and an “eCap” block

that records the “on” time and “period” of the PWM signal for display.

The following model is constructed. We have also included a “Monitor Buffer” to display the PWM

waveform in a “plot” block

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

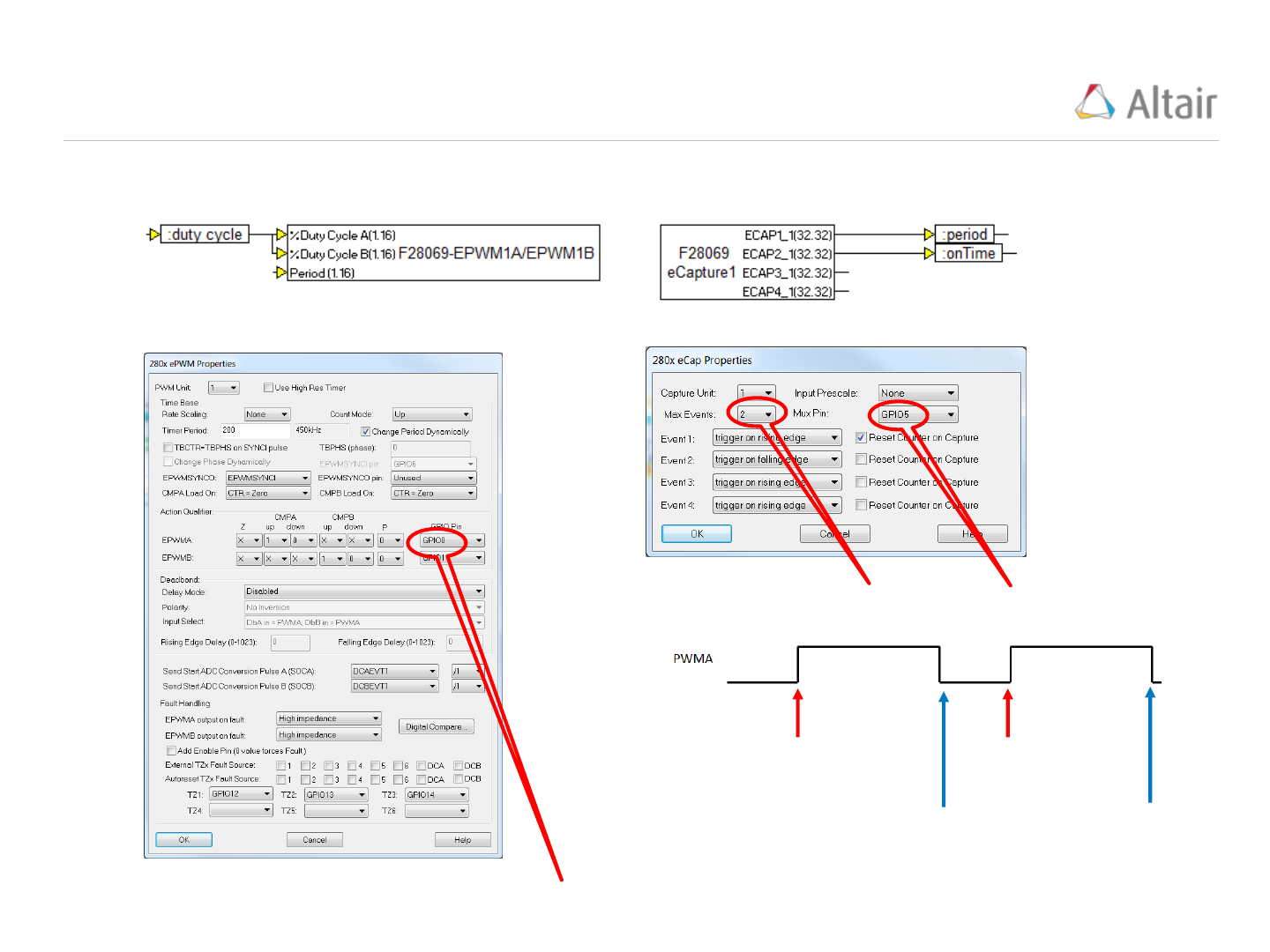

Record ePWM timing using eCap Block (2/5)

50

The “PWM” and “eCap” blocks are configured as follows:

PWM output (channel A) set to GPIO0

eCap input

set to GPIO5

Event 1

Triggers here &

timer is rest

Event 2

Triggers here

Record the

first 2 events

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

Record ePWM timing using eCap Block (3/5)

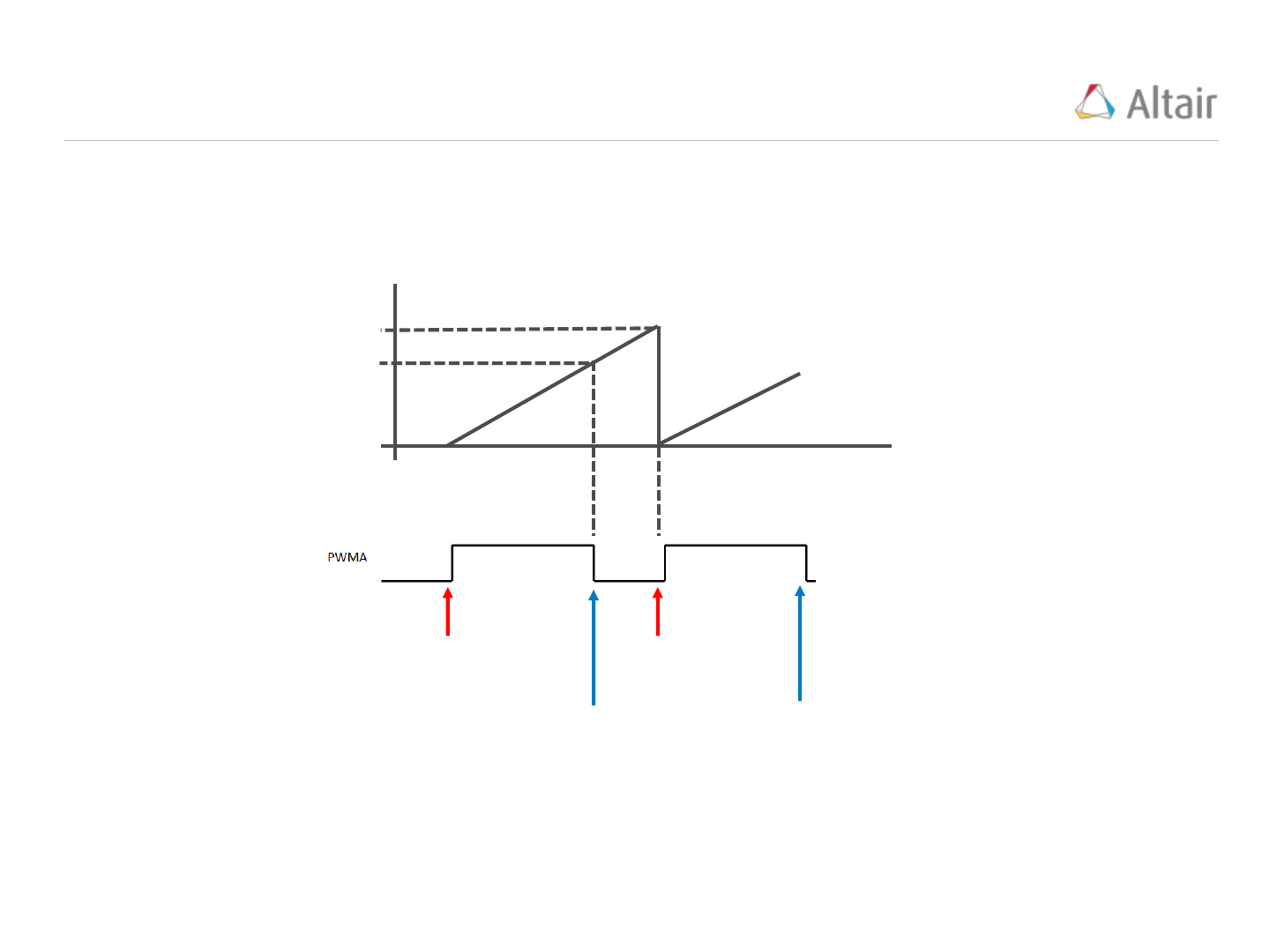

51

The “eCap” block is configured to output the values of the first 2 events. The following figure illustrates

how the event values are calculated.

Event 1

Triggers here &

timer is rest

Event 2

Triggers here

time

Timer count

Period

On time

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

Record ePWM timing using eCap Block (4/5)

52

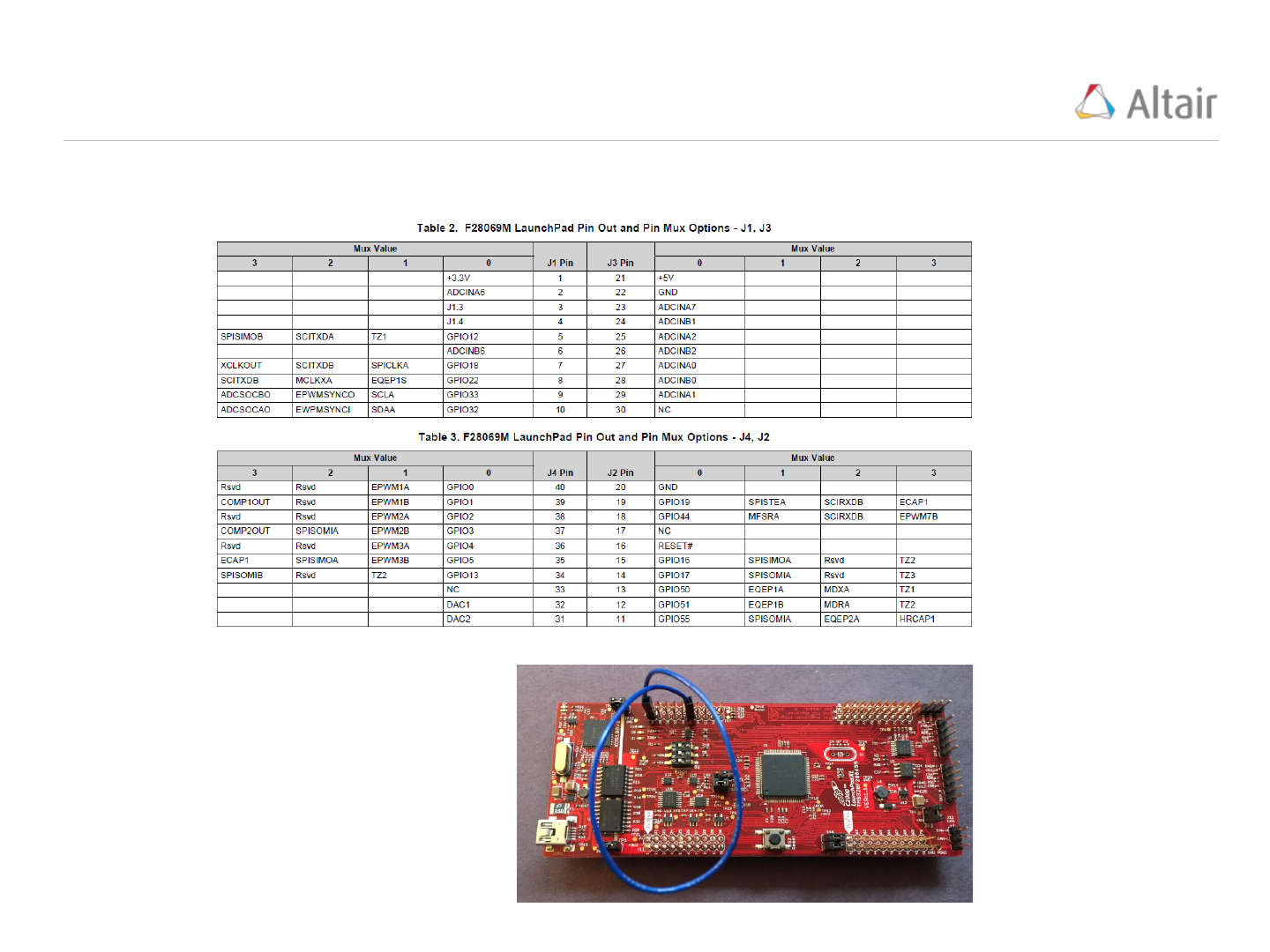

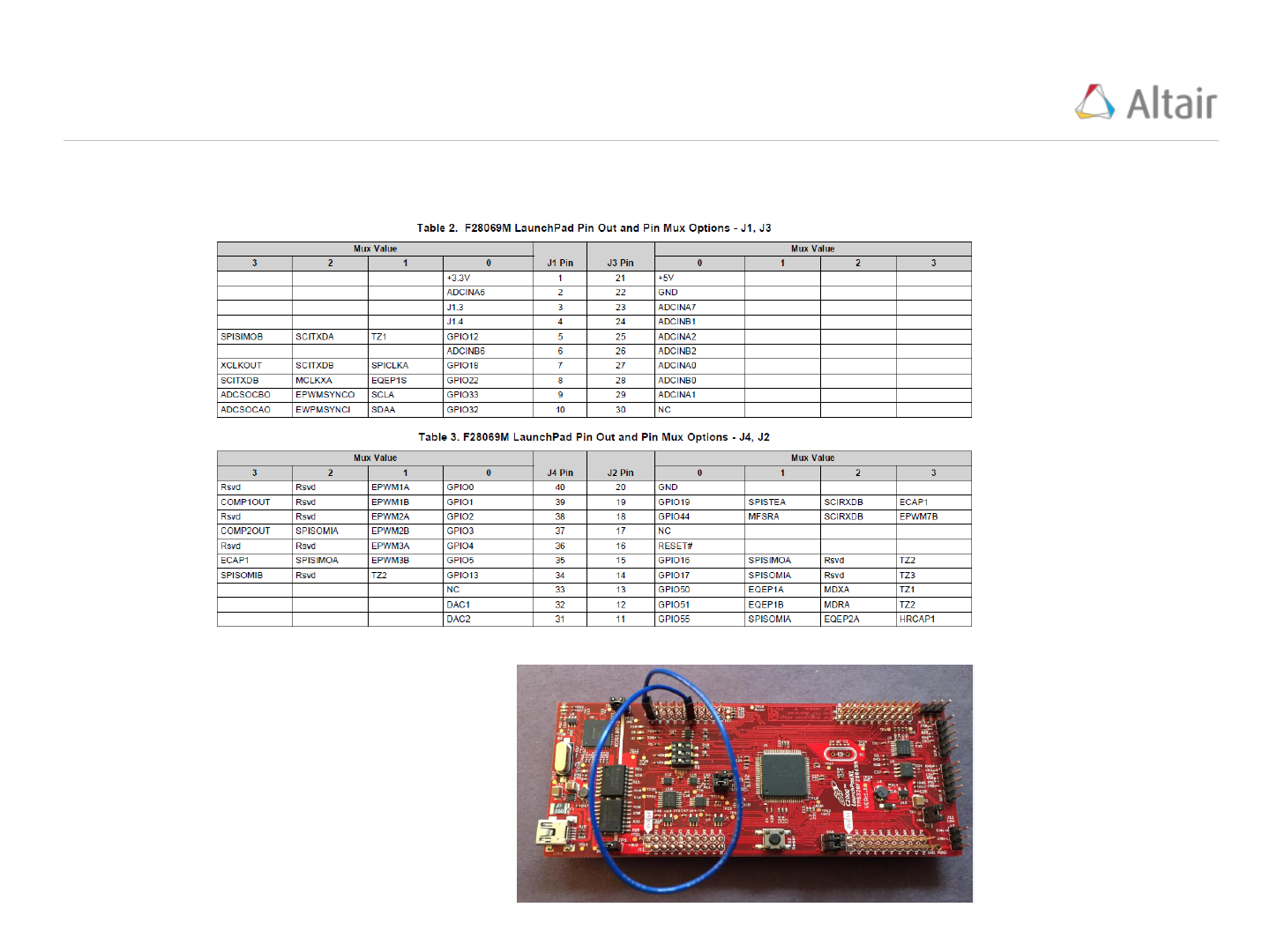

For the “eCap” block to operate, we need to jumper the pins that correspond to GPIO0 and GPIO5. The

pin definitions for the F28069M LaunchPad are presented below.

The jumper is positioned as

show to the right connecting pins

35 (GPIO5) and 40 (GPIO0)

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

Record ePWM timing using eCap Block (4/5)

54

For the “eCap” block to operate, we need to jumper the pins that correspond to GPIO0 and GPIO5. The

pin definitions for the F28069M LaunchPad are presented below.

The jumper is positioned as

show to the right connecting pins

35 (GPIO5) and 40 (GPIO0)

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

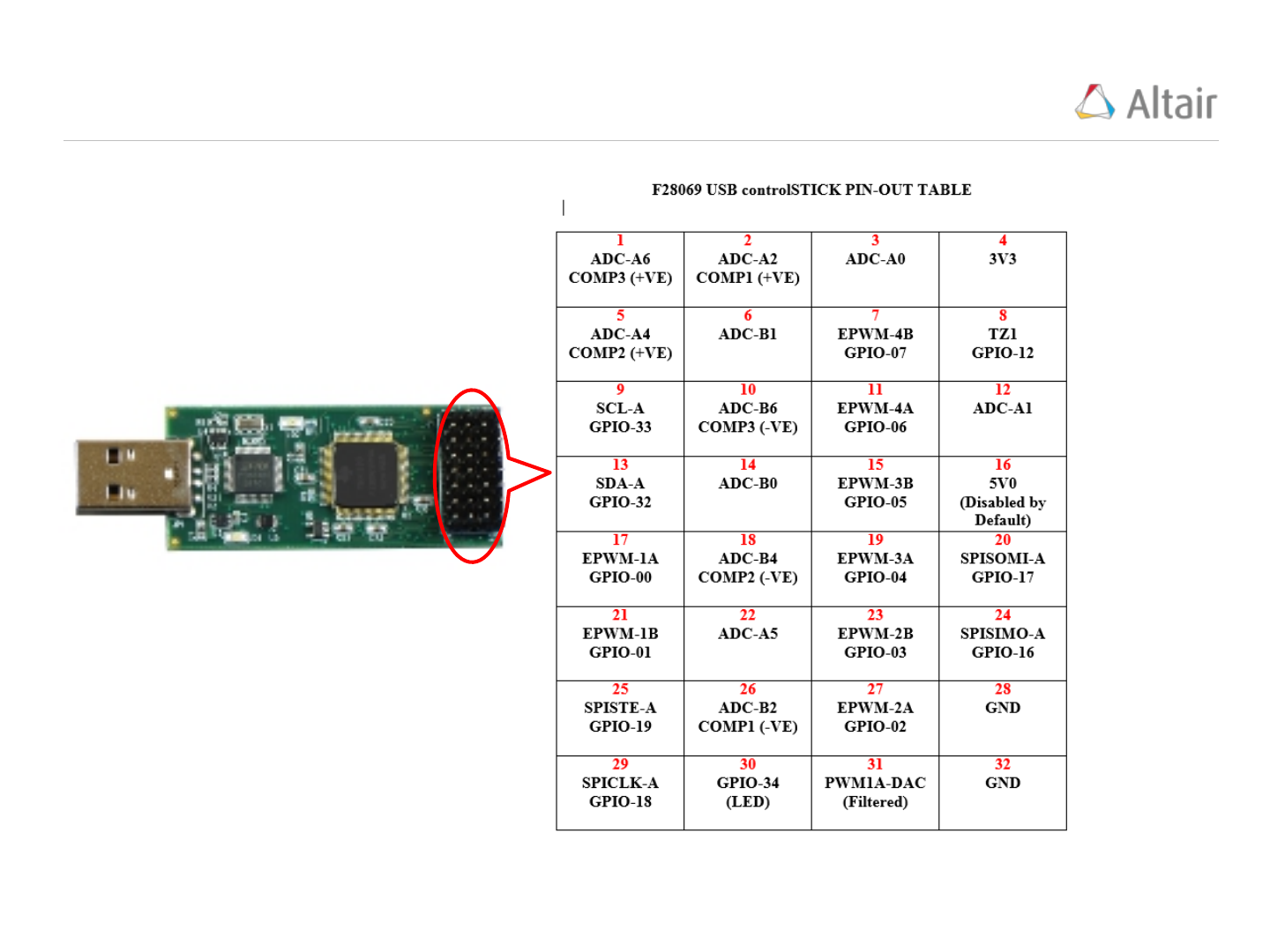

Pin Out definitions for F28069 ControlStick

55

Using the PWM and “eCap”

settings from the previous

example, the jumper settings for

the F28069 ControlStick

positioned as show to the right

connecting pins 15 (GPIO5) and

17 (GPIO0)

Copyright © 2015 Altair Engineering, Inc. Proprietary and Confidential. All rights reserved.

End of Section

56